How to Effectively Enhance the Performance of PDC Diamond Compacts

Polycrystalline diamond compact (PDC) is a superhard material composed of diamond powder and a cemented carbide substrate compounded under high-temperature and ultra-high-pressure conditions. It is widely used in industries such as petroleum and geological exploration, and mechanical machining tools. The cemented carbide substrate material, with its excellent toughness, hardness, and weldability, provides a solid foundation for the PDC. >>

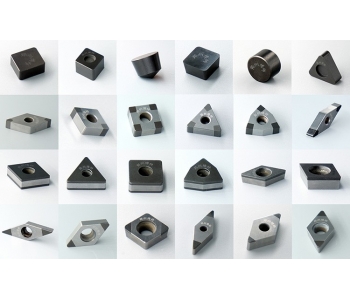

Advantages and Physical-Mechanical Properties of PCBN Inserts

PCBN (Polycrystalline Cubic Boron Nitride) inserts are ultra-hard cutting tools synthesized from cubic boron nitride (CBN) micro-powder and binders under ultra-high temperature and pressure. They are primarily used for machining difficult-to-machine materials such as cast iron and hardened steel. >>

Q&A: On the Selection of PCBN Inserts and PCD Inserts

However, although both PCD and PCBN belong to the category of superhard insert materials, they differ greatly in their cutting applications. When choosing between a PCD insert or a PCBN insert, it is essential to determine based on the actual machining situation to achieve better machining results. >>

Translation of CBN Insert Cutting Parameters Guide

Determining the optimal cutting parameters for CBN inserts is a dynamic process requiring comprehensive consideration of factors related to the workpiece, tool, machine tool, and machining requirements. Always use the recommended parameters provided by the CBN tool manufacturer (Berlt) as the starting point. Then, based on specific on-site conditions, through careful test cuts, meticulous observation, and systematic adjustments, find the optimal balance point among efficiency, cost, and quality. >>

CBN Inserts: The Secret Weapon for Machining Cast Iron and Hardened Steel

In the realm of efficiently processing high-hardness, high-wear-resistant materials, cubic boron nitride (CBN) tools have emerged as a critical solution due to their exceptional performance. Zhengzhou Berlt’s series of CBN insert grades, through scientifically optimized CBN content and binder formulations, enable targeted high-efficiency machining of cast iron materials (gray iron, wear-resistant alloy cast iron, high-chromium cast iron, ductile iron, chilled cast iron, etc.) and hardened steels (quenched steel, bearing steel, high-speed steel, high-manganese steel, wear-resistant steel, etc.). This offers manufacturing users more reliable and cost-effective solutions. >>

How to Improve the Wear Resistance of PCBN Composite Tool Materials

To ensure excellent wear resistance in CBN composite tool materials, Zhengzhou Berlt conducts extensive experimental analysis on every factor involved in the production process, laying a solid foundation for high-quality CBN composite tool materials. >>

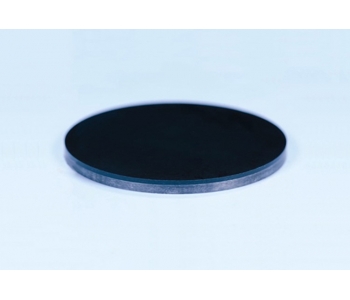

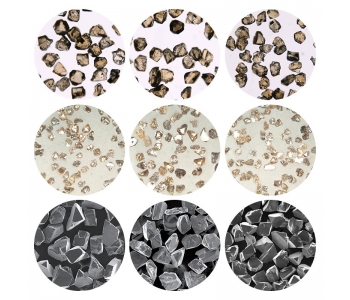

Characteristics and Application Advantages of DL8500 Series CBN Monocrystal

Zhengzhou Berlt's black DL8500 series CBN monocrystals utilize premium-grade hBN with complete crystal structure and minimal impurities. Through optimized synthesis protocols developed over years of research, the process employs highly active lithium-based multicomponent composite catalysts. Precise temperature control with uniform chamber heat distribution ensures controlled nucleation, followed by high-pressure phase transformation from hexagonal to cubic structure and crystal growth. The resulting black CBN crystals exhibit distinct edges, multiple crystal faces, and exceptional impact resistance. >>

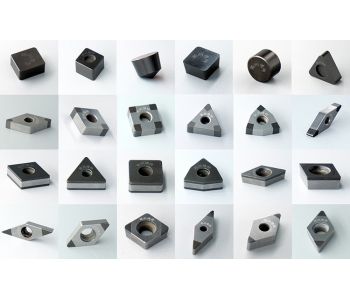

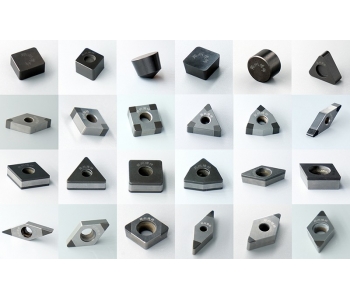

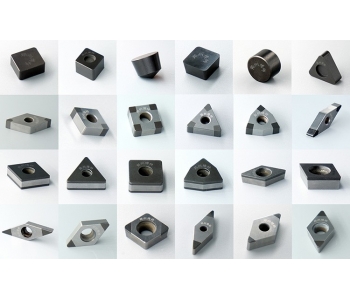

Structure and Grades of Zhengzhou Berlt CBN Inserts

CBN tools, as a type of superhard cutting tool, are manufactured by sintering CBN micropowder with a small amount of binder under ultra-high temperature and pressure. Due to their exceptional hardness, CBN tools are particularly suitable for machining materials with hardness exceeding HRC 50 and those with strong wear resistance. >>

actors Influencing the Performance of PDC Diamond Compact in Coal Geology Applications

PDC diamond compacts are synthesized by sintering a polycrystalline diamond layer onto a cemented carbide substrate under high-temperature and ultra-high-pressure conditions. Key factors affecting the quality and performance of the compact include the ratio of diamond to binder, the type of binder, diamond particle size, interfacial structure, and sintering processes. >>

A Comprehensive Guide to Ultra-Hard Tool Materials: Types, Characteristics, and Applications

In the cutting process system, machine tools, cutting tools, fixtures, and workpieces are the main components, with cutting tools being the most dynamic factor. High-performance tools combined with advanced processing equipment can maximize the efficiency of the entire cutting system, delivering significant economic benefits. >>

Technical Guide for Selecting CBN Abrasive Grain Sizes

When manufacturing CBN grinding wheels, different abrasive grain sizes impact surface quality, machining efficiency, durability, wheel speed, and other factors. Selecting the appropriate grain size is critical to achieving optimal results. So, what is CBN (cubic boron nitride) abrasive grain size, and how should the right grain size be chosen? >>

Optimization of Edge Treatment Process: Key Pathways to Enhance Performance of Berlt PCBN Inserts

In the modern high-precision machining field, polycrystalline cubic boron nitride (PCBN) tools have become the preferred choice for cutting hard materials due to their exceptional hardness and thermal stability. However, the ultimate performance of these tools depends not only on the material itself but also on the precision of edge treatment processes. Studies indicate that scientific edge treatment can extend tool life by over 300%, a result rooted in the dual logic of microstructural optimization and mechanical performance enhancement. >>