Key Advantages of Cubic Boron Nitride (CBN) Inserts in Machining High-Hardness Materials

Zhengzhou Berlt, as a pioneer in China's CBN cutting tool industry, owns one of the country's super-large CBN tool production bases. Its products cover over 90% of the domestic market in hard turning and heavy-duty cutting fields. With its self-built CBN (cubic boron nitride) material factory, it guarantees the quality of the insert raw materials from the source. The annual production capacity exceeds 6 million pieces of CBN inserts. Please feel free to contact us for technical support and application solutions regarding CBN inserts. >>

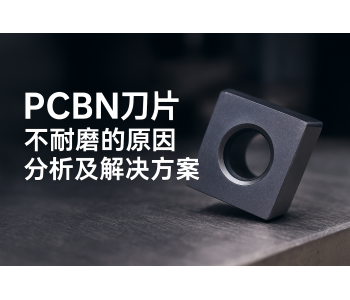

Analysis of PCBN Insert Wear Causes and Solutions

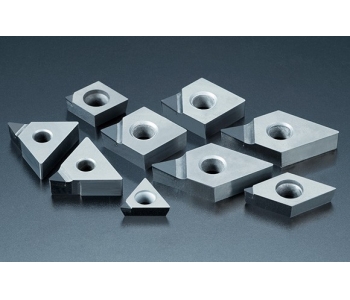

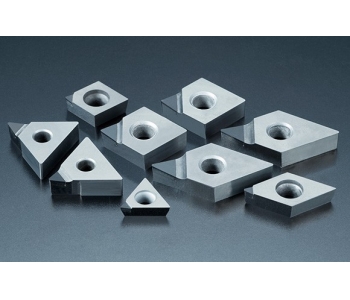

In the machining of high-hardness materials, PCBN (Polycrystalline Cubic Boron Nitride) inserts are highly favored due to their exceptional hardness and thermal stability. However, even ultra-hard materials are inevitably subject to wear. This article by Zhengzhou Bote will discuss the main causes of PCBN insert wear during actual cutting processes. >>

Analysis of Causes for Poor Wear Resistance of PCBN Inserts and Solutions

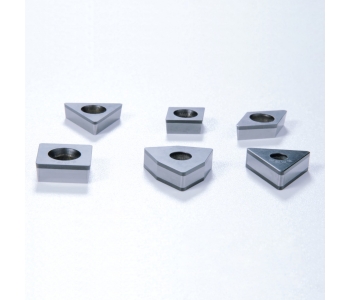

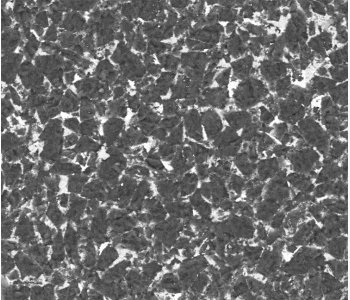

In the field of difficult-to-machine materials, PCBN (Polycrystalline Cubic Boron Nitride) inserts are widely used for efficient machining of hardened steel, cast iron, wear-resistant chilled cast iron, and other difficult-to-machine materials due to their high hardness, high wear resistance, and excellent thermal stability. >>

Specially for Boron Cast Iron! Berlt Introduces New PCBN Grade Dedicated to Boron Cast Iron Machinin

Berlt Company powerfully introduces a revolutionary solution: the new PCBN grade BT7500, specifically engineered for boron cast iron. This new grade integrates super toughness, extreme wear resistance, and high efficiency, completely resolving the difficulties in machining boron cast iron and helping you achieve a dual leap in production efficiency and tool durability! >>

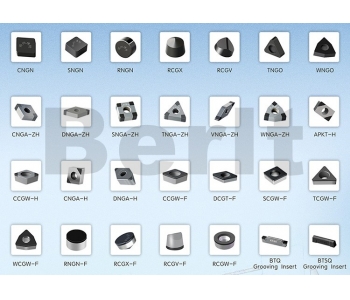

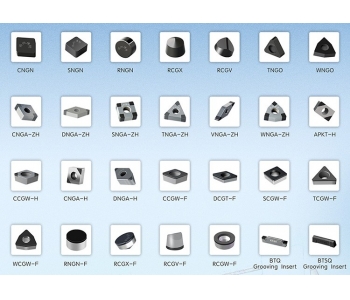

Berlt CBN Inserts Common Structural Forms

CBN inserts boast advantages like high wear resistance, excellent thermal stability, superior chemical stability, and a low friction coefficient. They enable turning instead of grinding and can achieve high machining precision and efficiency during high-speed cutting. According to the current specifications and models available on the market from Berlt, CBN inserts can generally be categorized into four common structural forms. >>

Frequent Machining Challenges? It Might Be Your PCBN Insert Edge Preparation That’s Incorrect!

In optimizing the overall performance of PCBN tools, the rational selection of edge preparation styles directly affects their service life and cutting efficiency. The actual choice requires systematic analysis based on various factors such as the physical characteristics of the workpiece material, cutting parameter configuration, specific working condition requirements, and tool substrate material. Below, based on years of technical practice by Berlt Superhard, a set of practical and reliable edge selection recommendations is compiled for industry reference. >>

Are CBN Inserts Not Performing Well? Understanding Common Issues and Solutions

As ultra-hard cutting tools for machining ferrous metals, especially high-hardness and difficult-to-machine materials, CBN inserts are widely used in processing cast iron, hardened steel, and other materials. >>

CBN Inserts vs. Ceramic Inserts: Different Performance and Applications

In the modern mechanical manufacturing industry, CBN (cubic boron nitride) inserts and ceramic inserts are two very typical types of cutting tool materials. With performance surpassing traditional cemented carbides, they have become essential tools for machining difficult-to-cut materials such as high-temperature alloys and hardened steel. >>

Optimization Guide for PCBN Insert Turning Cutting Parameters (Speed/Feed/Depth of Cut)

Throughout the turning process, cutting parameters encompass cutting speed, feed rate, and depth of cut. The selection of these parameters directly affects machining efficiency, machining quality, and tool life. The ideal cutting state includes: short cutting time, long tool life, and high cutting accuracy. To achieve good cutting results, reasonable cutting parameters must be selected based on the workpiece material, hardness, shape, and machine tool capability. >>

How to Correctly Use PCBN (Polycrystalline Cubic Boron Nitride) Cutting Tools

Within the entire cutting system, the proper use of the cutting tool significantly impacts the final cutting results. To fully leverage the characteristics of PCBN tool material, besides rationally selecting high-speed, high-rigidity machine tools and choosing appropriate tool material grades and cutting edge parameters, reasonable cutting parameters should also be selected based on specific machining conditions to better "match" the workpiece material being machined. >>

Performance and Applications of Polycrystalline Diamond (PCD) Cutting Tools

Sintering synthetic diamond under high temperature and high pressure produces polycrystalline diamond (PCD). PCD possesses excellent mechanical properties, such as extreme hardness and wear resistance, high thermal conductivity, and a low coefficient of friction. Based on these properties, PCD cutting tools have found wide applications in industry. >>

Selection and Application of Cutting Tool Materials in High-Speed Cutting

High-speed machining is a method of metal processing utilizing CNC machine tools, characterized by higher cutting speeds and feed rates. Consequently, the requirements for cutting tool materials are very stringent. Proper selection of cutting tool materials is crucial for ensuring the quality of high-speed machining. >>