In modern industrial manufacturing, grinding technology plays a vital role, with its indispensable contribution to enhancing product quality and production efficiency. Superhard abrasive tools, such as cubic boron nitride (CBN) wheels and diamond wheels, are highly favored for their excellent grinding performance. Although diamonds occupy a significant position in the grinding field due to their extremely high hardness and wear resistance, CBN abrasives demonstrate even more prominent advantages in specific situations, especially when grinding steel materials.

I. Comparison of Characteristics between CBN and Diamond Abrasives

Hardness and Strength:

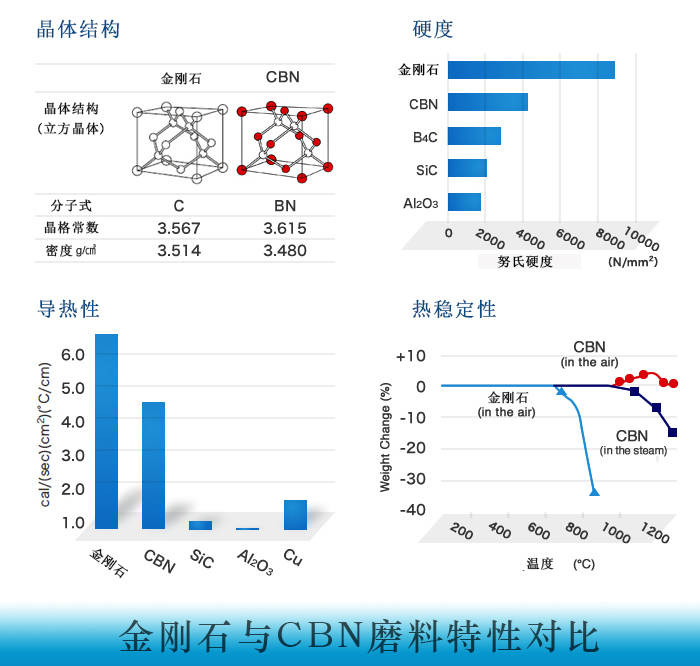

·CBN abrasives, as the second hardest material after diamonds, possess extremely high hardness and strength, meeting the requirements of most grinding tasks.

·Diamonds, on the other hand, have the highest hardness among abrasives but tend to undergo chemical reactions with ferrous materials at high temperatures, leading to accelerated wear.

Heat Resistance and Chemical Stability:

·CBN abrasives exhibit outstanding heat resistance and chemical stability, maintaining their inertness and hardness even at temperatures up to 1000°C, and are not prone to chemical reactions with ferrous materials.

·The chemical affinity of diamonds with ferrous materials at high temperatures results in accelerated wear, affecting grinding efficiency and workpiece quality.

II. Advantages of CBN Abrasives in Grinding Steel

Maintaining Sharp Cutting Edges:

·CBN abrasives can maintain sharp cutting edges during the grinding process, thereby improving grinding efficiency and workpiece surface finish.

Reducing Grinding Costs:

·Due to the excellent wear resistance and long service life of CBN abrasives, overall grinding production costs can be reduced, including the frequency of wheel replacement and grinding pressure.

Enhancing Production Capacity:

·The high metal removal rate and grinding efficiency of CBN abrasives shorten production cycles and enhance production capacity.

Improving Workpiece Quality:

·CBN abrasives can reduce residual stress or damage to parts during the grinding process, thereby improving the overall quality of the workpiece.

III. Conclusion

In summary, while diamond abrasives excel in grinding certain non-ferrous materials, CBN abrasives offer more advantages when grinding ferrous materials such as steel, thanks to their exceptional heat resistance, chemical stability, and wear resistance. Therefore, when selecting abrasives, comprehensive consideration should be given to factors such as the workpiece material, hardness, and grinding requirements to ensure optimal grinding results and economic benefits.