Berlt CBN Hard Turning Inserts | A Stability Solution for Hardened Steel Machining

From customer machining sites, common issues during the cutting process of hardened steel include chipping, fluctuating tool life, and poor machining consistency. Therefore, the core of selecting turning inserts for hardened steel lies not in single-cut performance, but in stability and controllability under long-term, batch processing conditions. >>

Leading Hard Turning: Application Analysis of CBN Inserts

Cubic Boron Nitride is currently the second hardest man-made superhard material after diamond. Unlike diamond, CBN possesses excellent thermal stability at high temperatures (withstandable above 1200°C) and has extremely high chemical inertness towards ferrous elements. >>

Berlt CBN Hard Turning Inserts | A Stable Machining Solution for High-Hardness Steels

Berlt CBN Hard Turning Inserts are precisely a mature solution developed to address this core need for hard steel machining. >>

Key Factors in Hard Turning, Starting with Berlt PCBN Hard Turning Inserts

"When other brands are still competing on hardness and price, Berlt has redefined the standard of 'ease of use' with an annual production capacity of 6 million inserts." — Zhengzhou Berlt In the field of hard turning, what truly >>

Hard Turning Instead of Grinding, Reducing Costs and Increasing Efficiency – Berlt CBN Hard Turning

Choosing Berlt CBN inserts means wind power bearing processing no longer has to be a "tough nut to crack," but can instead easily shift into "high gear." We look forward to becoming your reliable, long-term, and mutually beneficial partner. >>

Which Brand of CBN Inserts Performs Well: How Zhengzhou Berlt Became an Industry Benchmark

"While other brands are still competing on hardness and price, Berlt has already redefined the 'efficiency' standard with an annual production capacity of 6 million pieces." — Zhengzhou Berlt >>

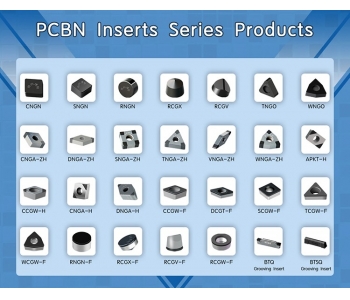

Analysis of the Advantages of Berlt PCBN Inserts in Machining Cast Iron and Hardened Steel

Zhengzhou Berlt CBN Inserts, as a pioneer in China's PCBN inserts industry, operates one of the country's largest CBN inserts production bases. Its products cover over 90% of the domestic market for hard and heavy-duty machining, with an annual production exceeding 6 million CBN inserts. Through continuous R&D on CBN raw materials and summarization of on-site machining experience, Berlt has developed specific CBN inserts grades suitable for turning different material properties based on their characteristics, meeting diverse machining objectives and requirements. >>

CBN Insert Brand Recommendation: A Guide to Choosing CBN Insert Manufacturers

Zhengzhou Berlt has been deeply engaged in the R&D and production of CBN inserts for over 20 years. Continuously researching and developing CBN tool materials matching the properties of the processed materials, it has developed a series of cubic boron nitride tool material grades for materials like cast iron and hardened steel, such as the BTS2800 series, BTS3800 series, BTS3100 series, BTS6000 series, BTS6500 series, etc., which can meet different machining application requirements. >>

Berlt PCBN Cutting Tools: Making Wind Turbine Bearing Turning More Efficient

Zhengzhou Berlt, focusing on PCBN tool machining solutions, provides professional PCBN tool support for machining high-hardness materials such as bearings and automotive components. Welcome to leave a message to discuss your machining challenges, and help accelerate Chinese manufacturing! >>

Key Factors Affecting the Performance of PDC cutters

The main factors affecting the quality and performance of the compact are the ratio of diamond to binder, the type of binder, the grain size of the diamond, the interface structure, and the sintering process, among others. >>

Causes and Countermeasures for Abnormal Wear of CBN Inserts

In the field of high-hardness material machining, CBN inserts are widely used due to their excellent wear resistance and thermal stability, especially suitable for turning materials like cast iron and hardened steel. >>

Analysis of Cutting Principles of CBN Inserts

Cubic Boron Nitride (CBN) inserts are one of the preferred tools for machining high-hardness materials (HRC50-65) and difficult-to-machine materials. Compared with traditional carbide tools, CBN has extremely high hardness and thermal stability, enabling high-precision and high-efficiency machining on workpiece materials such as cast iron and hardened steel. >>