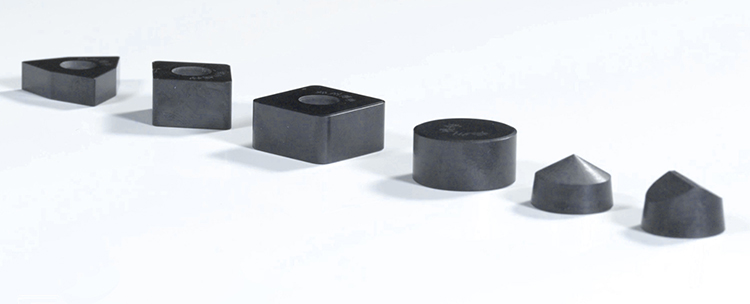

In the pursuit of ultimate efficiency and precision in modern machining, cubic boron nitride (CBN) inserts have become a powerful tool for machining high-hardness ferrous metals, thanks to their hardness second only to diamond and exceptional thermal stability.

However, whether or not to use cutting fluid (commonly known as "adding water") directly impacts tool life, machining costs, and the final quality of the workpiece. So, when using CBN inserts, should you add water or not?

The answer is: Generally not recommended. For cubic boron nitride (CBN) inserts, the use of water-based cutting fluids for cooling and lubrication is usually not advised. "Dry cutting" is the most commonly used and recommended machining method for CBN inserts.

Why is "Dry Cutting" Mostly Used with CBN Inserts? This is determined by their material properties and machining objectives.

1、Exceptional Thermal Stability

CBN material possesses extremely high thermal stability, far exceeding that of diamond. It can maintain hardness and strength at cutting temperatures as high as 1000°C and above. This means it can inherently withstand the high temperatures generated by dry cutting without relying on cutting fluid for forced cooling.

2、Avoiding Thermal Shock and Chemical Reactions

During intermittent cutting, if coolant is used, the tool undergoes severe "heating-cooling" cycles, which can easily cause micro-cracks due to thermal stress, ultimately leading to chipping. Furthermore, at high temperatures, CBN can undergo adverse chemical reactions with water.

3、Leveraging Material Advantages for "Turning Instead of Grinding"

The core advantage of CBN inserts lies in efficiently machining high-hardness materials (such as hardened steel, chilled cast iron), enabling "turning instead of grinding." Dry cutting can fully utilize their red-hardness at high temperatures, maintaining a sharp cutting edge and achieving good surface finish.

Of course, there are exceptions. In certain specific working conditions (such as those sensitive to thermal deformation), the use of cutting fluid (not pure water, usually specialized oil-based or emulsions) is necessary or even beneficial. The key lies in adhering to the principle of "either supply abundantly or do not use it at all" to avoid the risk of thermal cracking caused by uneven cooling.