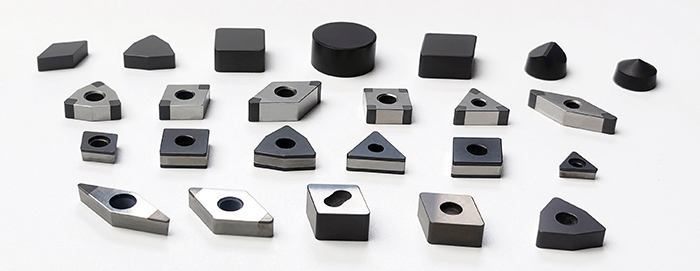

What is Cubic Boron Nitride (CBN) Tooling?

Cubic Boron Nitride (CBN) is a synthetic superhard material manufactured through high-temperature and high-pressure (HPHT) technology. Its hardness and high-temperature resistance far exceed those of traditional carbide and ceramic tools, making it particularly suitable for machining high-hardness, wear-resistant materials such as hardened steel, chilled cast iron, and gray cast iron.

Five Core Characteristics of CBN Tools

Exceptional Hardness & Wear Resistance

CBN ranks second only to diamond in hardness (microhardness: 8,000–9,000 HV), >50x harder than carbide.

Application: Machining hardened steel (e.g., HRC 60 gears) achieves >10x longer tool life vs. carbide tools.

High-Temperature Stability for High-Speed Machining

Maintains performance stability at 1,200°C, enabling 300 m/min cutting speeds for cast iron.

Application: Triples machining efficiency in cast iron components.

Chemical Inertness & Anti-Built-Up Edge (BUE)

Minimal chemical reactivity with Fe/steel alloys at elevated temperatures, eliminating adhesion.

Application: Achieves Ra ≤ 0.4 μm surface finish on titanium alloys, reducing polishing steps.

Impact Resistance for Interrupted Cutting

Engineered geometries (e.g., reinforced edges) mitigate chipping risks in discontinuous cuts.

Application: Gear keyway machining in automotive transmissions extends tool life 5x.

Turning-to-Grinding Precision, Cost Efficiency

Directly achieves grinding-level accuracy (Ra ≤ 0.8 μm) via turning, eliminating grinding steps.

Case Study: A manufacturer reduced per-part cost from ¥8 to ¥3 by replacing grinding with CBN turning.

Materials Suitable for CBN Tools

Hardened Steel (HRC 45+)

Applications: Bearing steel (e.g., GCr15), die steel (e.g., H13) for gears, bearings.Chilled Cast Iron

Applications: Mill rolls, engine cylinder liners requiring extreme wear resistance.Gray Cast Iron

Applications: Engine blocks, brake discs, drums, flywheels, clutch plates.

Guidelines for Using CBN Tools

Material Compatibility

Avoid low-hardness materials (e.g., stainless steel, aluminum) to prevent accelerated flank wear.

Parameter Optimization

Continuous cutting: Higher speeds (e.g., Vc = 250 m/min for gray iron)

Interrupted cutting: Reduce feed (f ≤ 0.2 mm/rev) to avoid edge chipping

Tailor cutting parameters (Vc, f, ap) to workpiece material and operation type:

Critical Avoidances

High-speed steel (HSS) machining: Limit Vc < 80 m/min to prevent thermal softening.

Interrupted cuts: Use impact-resistant grades (e.g., Sandvik CB70) with honed edges.