PCBN cutting tools demonstrate outstanding performance in machining high-hardness ferrous metals (e.g., hardened steel, cast iron) due to their ultra-high hardness and excellent impact resistance.

Different PCBN insert models correspond to distinct structural designs, machining scenarios, and performance characteristics. This article systematically explains the naming conventions and application scenarios of Berlt PCBN inserts.

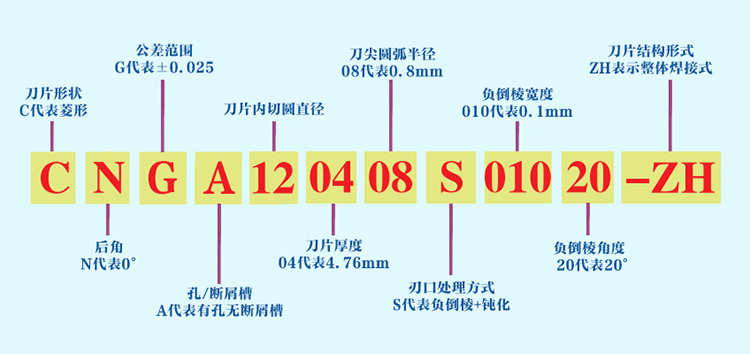

Berlt PCBN inserts typically combine core information such as shape, relief angle, tolerance, hole type, dimensions, nose radius, cutting edge type, and insert structure through alphanumeric codes to intuitively reflect insert properties. Taking CNGA120408S01020-ZH as an example, its designation is decoded as shown in the figure below:

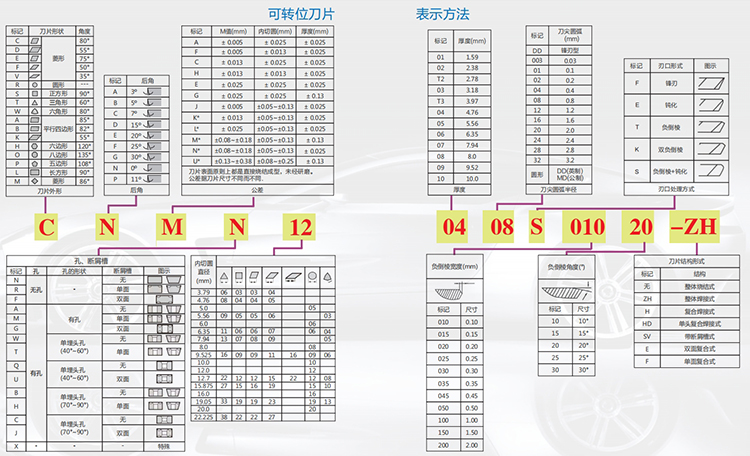

Different letters and positions represent specific meanings. The figure below illustrates common designation rules for indexable inserts:

By understanding the model designation rules, you can quickly select compatible PCBN inserts to achieve both efficiency and quality improvements in high-hardness material machining! Berlt has over 20 years of expertise in the PCBN insert industry, having initiated large-scale production and sales of PCBN inserts since 2002, further enhancing the competitive advantages of tool distributors.