When manufacturing CBN grinding wheels, different abrasive grain sizes impact surface quality, machining efficiency, durability, wheel speed, and other factors. Selecting the appropriate grain size is critical to achieving optimal results. So, what is CBN (cubic boron nitride) abrasive grain size, and how should the right grain size be chosen?

I. What Is CBN Abrasive Grain Size?

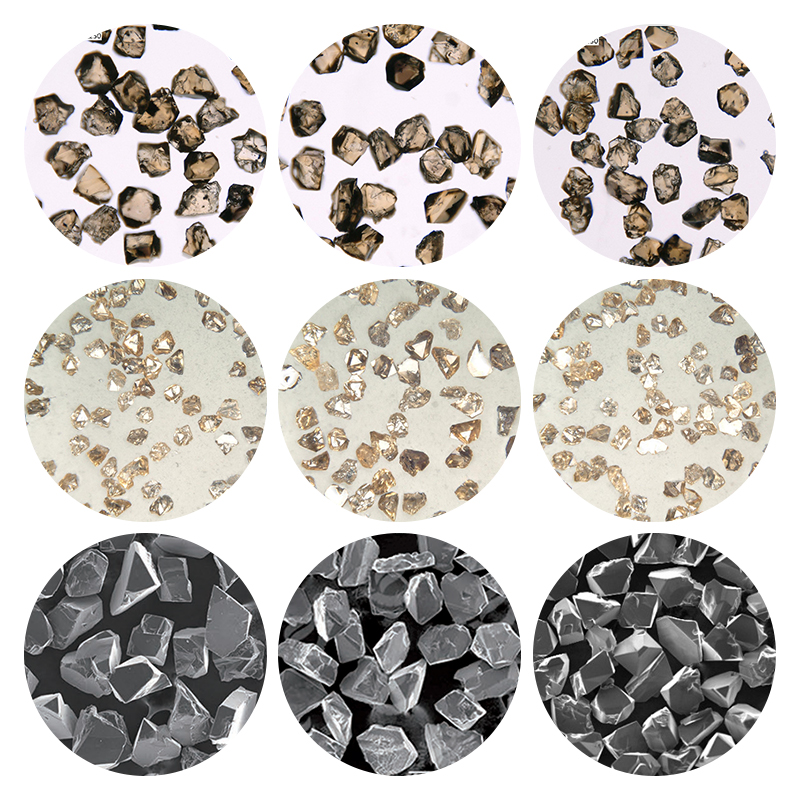

Abrasive grain size, more accurately termed "particle size composition," refers to the range of particle sizes in CBN abrasives. Commonly cited grain size designations like "80/100," "100/120," or "120/140" represent specific size ranges, including the coarsest grains, coarse grains, base grains, fine grains, and finest grains.

Grain size designation identifies the coarseness or fineness of abrasives. In China’s national standard, the screening method is used for verification. For example, the CBN 100/120 grain size corresponds to a nominal sieve aperture range of 125–150 μm, meaning the CBN particles are retained between sieves with 150 μm and 125 μm apertures.

Key definitions:

Coarsest grains: Particles retained on the upper limit sieve.

Coarse grains: Particles retained on the upper inspection sieve.

Base grains: Particles retained on the lower inspection sieve.

Fine grains: Particles passing through the lower inspection sieve.

Finest grains: Particles passing through the lower limit sieve.

II. How to Select the Appropriate CBN Grain Size?

CBN grain size directly affects grinding quality, particularly surface roughness. To achieve desired surface finish, proper grain size selection is essential.

1. General Selection Principles

Due to CBN’s sharpness and wear resistance, to achieve the same surface roughness as conventional abrasives, CBN grain sizes should be 1–2 grades finer.

If surface roughness requirements are met, prioritize coarser grains to enhance machining efficiency.

2. Selection Based on Bond Type

Resin-bonded CBN wheels: Use grain sizes 100/120 or finer.

Metal-bonded CBN wheels: Use grain sizes 80/100–270/325.

Vitrified-bonded CBN wheels: Select grain sizes between the above ranges.

3. Selection Based on Machining Requirements

Coarse grains are recommended for rough grinding with large grinding depths and heavy material removal.

Fine grains are ideal for precision grinding with small grinding allowances and high accuracy requirements.