CBN tools, as a type of superhard cutting tool, are manufactured by sintering CBN micropowder with a small amount of binder under ultra-high temperature and pressure. Due to their exceptional hardness, CBN tools are particularly suitable for machining materials with hardness exceeding HRC 50 and those with strong wear resistance.

What is CBN Material?

CBN (Cubic Boron Nitride) is synthesized from hexagonal boron nitride ("white graphite") under high temperature and pressure. As the second-generation superhard tool material developed after synthetic diamond, CBN is a non-metallic boride. Its hardness is second only to diamond and far surpasses that of high-speed steel and cemented carbide. Consequently, CBN tools outperform cemented carbide tools in machining materials that are difficult to cut.

Suitable Materials for CBN Tools

CBN tools are ideal for cutting:

· Hardened steels (bearing steel, mold steel, etc.)

· Cast irons (gray iron, ductile iron, high-chromium iron, alloy wear-resistant iron, etc.)

· High-speed steel

· Cemented carbide

· Heat-resistant alloys

They exhibit significant advantages in ferrous metal machining.

Note: CBN tools are not recommended for soft metals or non-metallic materials. They should only be used when material hardness reaches HRC >50.

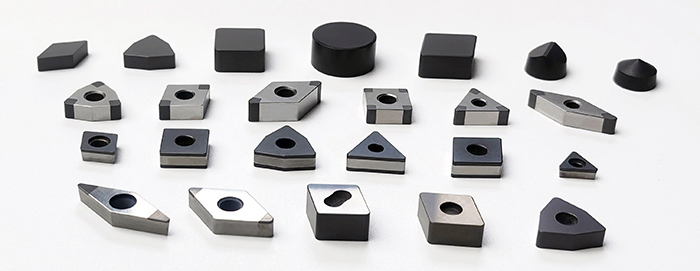

Common Structural Forms of CBN Inserts

In turning applications, CBN tools typically adopt the following structures:

1、Solid CBN Inserts

Entirely sintered from CBN micropowder. Features multiple cutting edges with reversible cutting tips, high material utilization rate. Offers high bending strength, suitable for heavy-depth high-speed cutting in continuous, light-interrupted, or heavy-interrupted conditions. Applicable for roughing, semi-finishing, and finishing.

2、 Brazed CBN Inserts

Fully welded structure with central hole positioning, capable of directly replacing coated inserts. Suitable for machining with cutting depth <2mm, light-interrupted or continuous conditions. Designed for semi-finishing and finishing.

3、Composite Brazed CBN Inserts

Small CBN segments brazed onto carbide substrates to form turning or boring inserts. Single cutting edge available, primarily used for precision finishing.

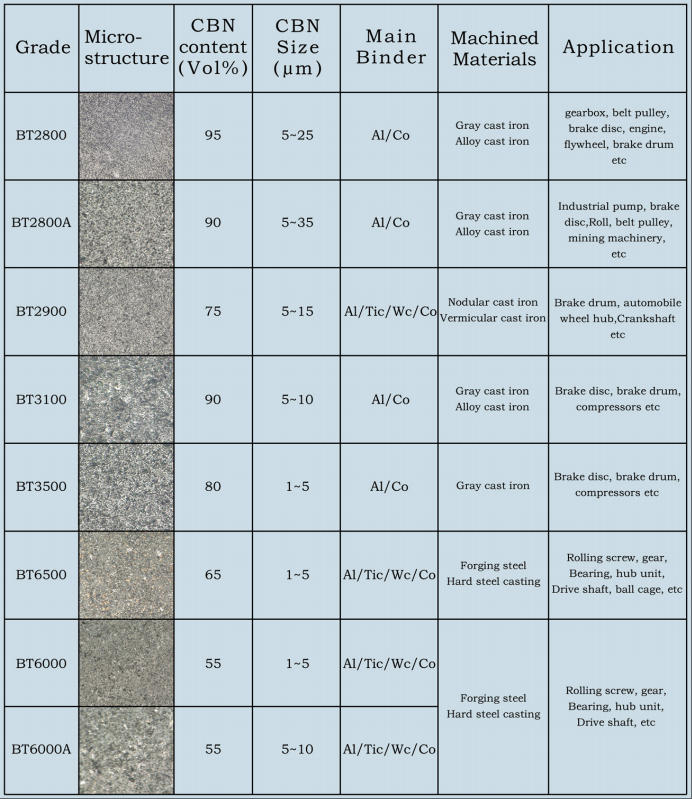

CBN Tool Grades

Different grades are classified based on variations in CBN content, particle size, and binder composition to address specific material machining requirements. Prior to selection, consult Bote tooling engineers to determine the optimal grade for your workpiece material and processing conditions.

Typical Application Industries

CBN tools are widely utilized globally, especially in challenging material processing sectors:

· Automotive Manufacturing: Engine components, crankshafts, brake discs/drums

· Mining Machinery: Concave walls, slurry pumps

· Bearing & Gear Industry: Hub bearings, slewing rings, wind turbine bearings, gears

· Rolling Mill Sector: Cast iron rolls, high-speed steel rolls