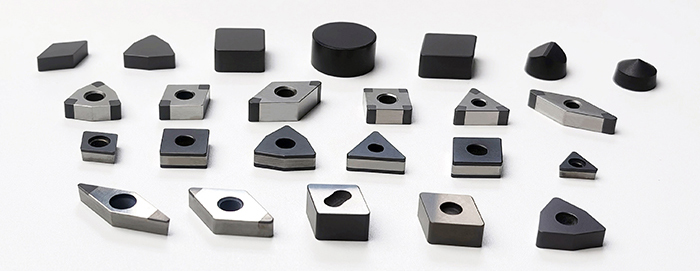

In the realm of efficiently processing high-hardness, high-wear-resistant materials, cubic boron nitride (CBN) tools have emerged as a critical solution due to their exceptional performance. Zhengzhou Berlt’s series of CBN insert grades, through scientifically optimized CBN content and binder formulations, enable targeted high-efficiency machining of cast iron materials (gray iron, wear-resistant alloy cast iron, high-chromium cast iron, ductile iron, chilled cast iron, etc.) and hardened steels (quenched steel, bearing steel, high-speed steel, high-manganese steel, wear-resistant steel, etc.). This offers manufacturing users more reliable and cost-effective solutions.

Core Advantages of CBN Inserts

Compared to traditional carbide tools, CBN inserts demonstrate unparalleled hardness (typically 30–50 times higher) and extraordinary wear resistance, significantly extending tool life. Against ceramic tools, CBN inserts exhibit markedly superior impact resistance and fracture toughness. This ensures stable performance even under demanding conditions requiring high metal removal rates or involving interrupted cuts (e.g., roughing, heavy cuts), effectively preventing chipping and fracture to guarantee machining continuity and safety.

High-CBN Grades: The Wear-Resistant Solution for Cast Iron

Addressing the core demand for extreme wear resistance in cast iron machining, Berlt’s high-CBN grades (e.g., BTS2800, BTS3800, BTS7800, BTS9000 series) maximize CBN particle content to significantly enhance insert durability, making them ideal for processing various cast irons.

These grades balance toughness and wear resistance, effectively combating common wear in cast iron machining while mitigating chipping risks. They perfectly adapt to high-volume, high-efficiency machining needs for components like rolls, industrial pumps, and automotive brake discs.

Medium/Low-CBN Grades: Balancing Toughness and Wear Resistance for Hardened Steel

When machining hardened steels such as quenched steel, bearing steel, and tool steel, Berlt’s medium/low-CBN grades (e.g., BTS6000, BTS6000A, BTS6500 series) demonstrate unique advantages. By optimizing CBN content, these grades provide enhanced impact strength and balanced toughness.

They offer sufficient hardness and wear resistance while effectively resisting shocks from hard-brittle materials, exhibiting outstanding resistance to crater wear. This makes the BTS6000 series a superior solution for precision machining of hardened steel components like gears, bearings, and molds, ensuring stable processing and surface quality.

CBN tool technology continues to evolve toward finer material adaptability and optimized performance. By differentiating high-CBN and medium/low-CBN grades while deeply optimizing for the distinct machining characteristics of cast iron and hardened steel, next-generation CBN tools provide manufacturing users with a more precise and efficient weapon to overcome high-hardness material machining challenges.