Berlt Cutting Tools PCBN Discs: Product Characteristics and Application Advantages

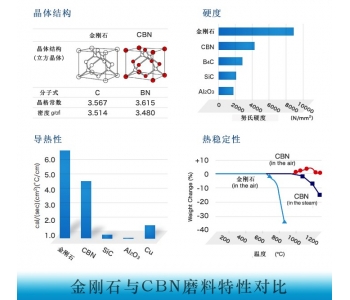

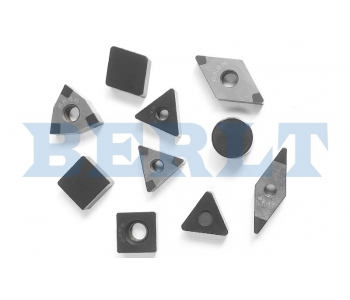

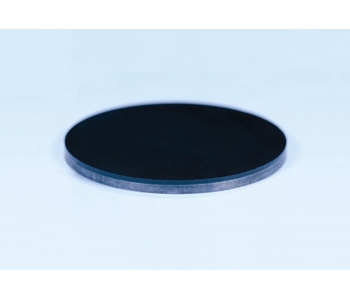

Polycrystalline Cubic Boron Nitride (PCBN) discs are ultra-hard tool materials composed of cubic boron nitride (CBN) micropowder sintered with metal or ceramic binders under high temperature and pressure, and then combined with a carbide substrate. Leveraging their exceptional physical and chemical properties, Zhengzhou Berlt PCBN discs excel in high-hardness material processing, high-speed cutting, and challenging machining applications, gradually becoming a critical replacement for traditional tools in modern manufacturing. >>

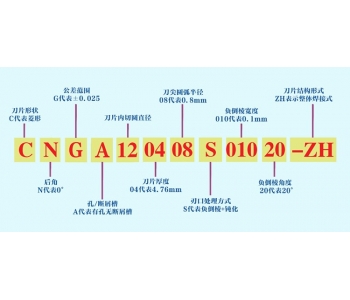

Model Designation System for Berlt PCBN Cutting Tools Inserts

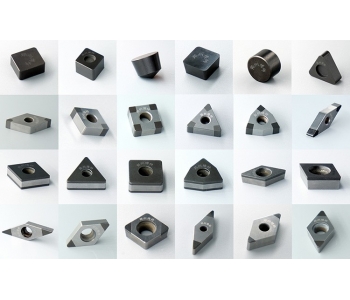

PCBN cutting tools demonstrate outstanding performance in machining high-hardness ferrous metals (e.g., hardened steel, cast iron) due to their ultra-high hardness and excellent impact resistance. >>

Characteristics and Application Scenarios of CBN Cutting Tools

Cubic Boron Nitride (CBN) is a synthetic superhard material manufactured through high-temperature and high-pressure (HPHT) technology. Its hardness and high-temperature resistance far exceed those of traditional carbide and ceramic tools, making it particularly suitable for machining high-hardness, wear-resistant materials such as hardened steel, chilled cast iron, and gray cast iron. >>

Determination of Cutting Parameters for Cubic Boron Nitride (CBN) Inserts

When determining the cutting parameters for cubic boron nitride (CBN) inserts, it is essential to comprehensively consider multiple factors, including the characteristics of the workpiece material, the type and geometry of the insert, machine tool performance, and desired machining quality. Below are key cutting parameters and their determination methods: >>

Unlocking the scientific and technological code of wear resistance of BERLT Cubic Boron Nitride comp

2024/12/30

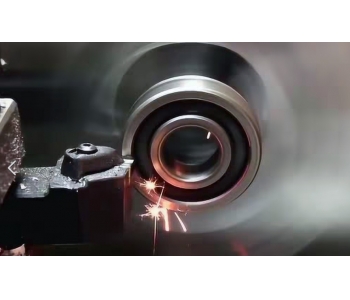

In today's precision manufacturing arena, tool wear resistance is undoubtedly one of the key factors in determining production efficiency and machining accuracy, and Cubic Boron Nitride composite tool material is like a shining star, attracting attention. >>

What is the solution to the CBN insert cutting heat problem?Four strategies to open the "heat c

2024/12/23

In this paper, we will discuss how to effectively control the increase of cutting heat during the cutting process of CBN inserts, covering several key aspects such as optimisation of cutting parameters, optimisation of tool geometry, use of cutting fluids and stability of the machining system. >>