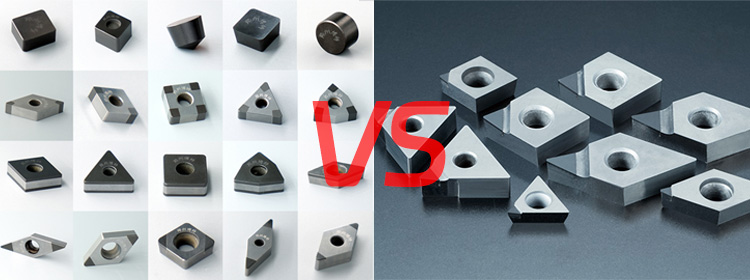

Polycrystalline diamond (PCD) and polycrystalline cubic boron nitride (PCBN) insert materials rank first and second, respectively, among the hardest known insert materials in nature and are therefore collectively referred to as superhard inserts.

However, although both PCD and PCBN belong to the category of superhard insert materials, they differ greatly in their cutting applications. When choosing between a PCD insert or a PCBN insert, it is essential to determine based on the actual machining situation to achieve better machining results.

·What is the biggest difference between PCD inserts and PCBN inserts?

PCD inserts are the first choice for machining materials such as aluminum alloys, magnesium alloys, carbon fiber, and ceramics. When machining these non-ferrous materials, the extremely high hardness of PCD inserts provides excellent tool life and surface quality. However, PCD inserts are not suitable for machining ferrous materials (such as steel and cast iron) because at high temperatures, the carbon atoms in PCD react with the workpiece material, causing rapid insert wear.

PCBN insert material is chemically inert to ferrous metals and can withstand temperatures exceeding 1400°C. It does not undergo chemical reactions with ferrous materials even at 1200~1300°C. During high-temperature cutting, it does not exhibit rapid wear phenomena. Therefore, it is particularly suitable for cutting cast iron and hardened steel materials.

·When using PCD or PCBN inserts, is coolant necessary?

When using PCD inserts for turning, the use of coolant is recommended. When using PCBN inserts for turning, the use of coolant is not recommended. Of course, whether or not to use coolant also depends on the actual situation. The purpose of coolant is to reduce the temperature in the cutting zone. As long as the coolant is properly applied, it helps extend tool life and aids chip evacuation.

·Is edge preparation important for PCD and PCBN inserts?

Very important. Reasonable edge preparation methods can enhance the edge strength of the insert and also control chip flow direction. Furthermore, almost every insert has microscopic edge imperfections before edge preparation. Edge preparation can, to a certain extent, eliminate defects that could lead to unstable machining performance.

·How should the cutting parameters for PCD and PCBN inserts be determined?

Determining the optimal cutting parameters for an insert is a process that comprehensively considers factors such as the workpiece, tool, machine tool, and machining requirements. It is necessary to comprehensively consider factors such as workpiece material, hardness, machining conditions, the machine tool's own conditions and stability, and the inherent characteristics of the insert to find the optimal balance point that balances efficiency, cost, and quality.