The toolholder is an important part of the turning system, and the toolholder also has different compression methods at the same time.

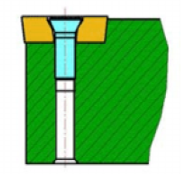

First, the pressure plate pressure type For the insert without holes, especially with the rear corner of the insert, often using the pressure plate pressure type. This type of compression has many advantages, first of all, its clamping force is large, can firmly fix the insert, ensure that the insert will not be loose in the turning process. Secondly, high stability, can effectively resist the impact of cutting force, to ensure machining accuracy. Further, easy to clamp, the operator can quickly install and replace the insert, improve work efficiency. Finally, it is easy to manufacture and reduces the production cost. Specifically as shown in the figure below.

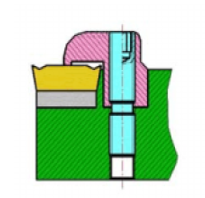

Second, composite compression type (M) When facing the insert with holes, usually use the pin positioning and pressure plate composite compression. The clamping force and stability of this structure is higher than that of the platen clamping type, so it is quite widely used in the roughing of the inner hole of the outer circle. It ensures that the position of the insert is accurate through the pin positioning, coupled with the tightening effect of the pressure plate, making the insert more stable and reliable in the machining process. However, the above two clamping methods also have major disadvantages, namely, due to the front structure, resulting in a larger size to the head, which may be restricted in some machining occasions with limited space. Specifically as shown in the figure below.

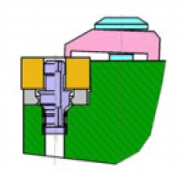

Third, the lever compression type (P) Lever type clamping mechanism has two structural forms of straight rod type and curved rod type. Usually more commonly used is the curved lever lever pressing mechanism. In this structure, the blade is clamped by the curved rod through the screw. The curved rod swings with its corner projection as the pivot point, and when the screw moves up and down, the lever cooperates with the grooves on the screw to realize clamping and loosening. The spring-loaded sleeve is semi-cylindrical, and the cutter pad is positioned on the cutter bar by the tension of the spring-loaded sleeve. There is a large gap between the spring sleeve and the crankshaft, which makes it easy for the crankshaft to swing between them. This clamping method has a certain degree of flexibility to adapt to different shapes and sizes of blades, but also has a good clamping force and stability. Specifically as shown in the figure below.

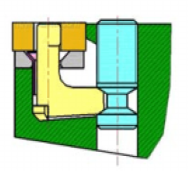

Fourth, the screw compression type (S) with countersunk head screws to fasten the blade is a common way of compression. This structure is compact, will not take up too much space, especially for the chip space and tool head size requirements. The manufacturing process is simple and reduces production costs. Moreover, the clamping is reliable and the positioning accuracy is guaranteed by the positioning surface of the tool body, which can meet the requirements of high-precision machining. Usually in the finishing process are used in the screw pressure type, to ensure the processing quality and accuracy. Specifically as shown in the figure below.