Machining accuracy

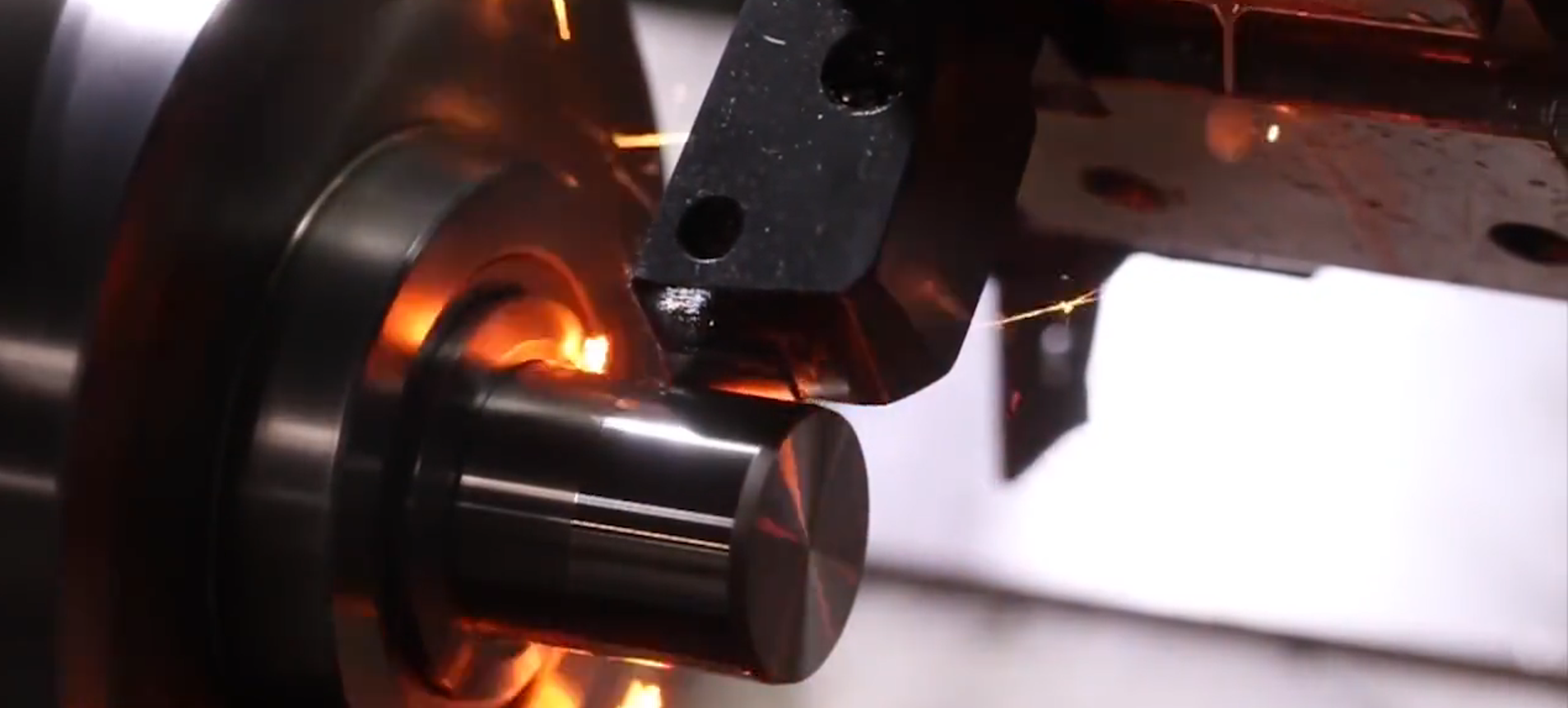

Dimensional accuracy,Good machine rigidity can ensure that the relative position between the tool and the workpiece remains stable during CBN tool turning machining. When the rigidity of the machine tool is not enough, the machine tool may undergo a small deformation during the machining process, resulting in the actual cutting position of the tool and the expected position of the deviation, thus affecting the machining dimensional accuracy.

For example, when machining high-precision shaft parts, poor machine tool rigidity may cause the diameter size of the shaft to fluctuate out of tolerance.

Shape accuracy,For complex shaped workpieces, the rigidity of the machine tool has a more obvious effect on the shape accuracy. If the rigidity of the machine is not enough, under the action of the cutting force, the machine components may be elastic deformation, so that the shape of the machined workpiece does not match the design requirements.Such as the processing of cylindrical surfaces, there may be ellipticity, taper and other shape errors.

Second, the surface quality

Roughness,Good rigidity of the machine tool can reduce the vibration of the machining process, so that the CBN tool in the cutting more smoothly. This can reduce the roughness of the surface of the workpiece to obtain a smoother machined surface.Conversely, if the machine tool rigidity is poor, vibration can cause the tool to leave uneven cutting marks on the workpiece surface, increasing surface roughness.

Surface Integrity,Adequate machine rigidity helps ensure that CBN tools machine with stable cutting parameters, reducing thermal and mechanical stresses caused by changes in cutting forces. This helps to improve the surface integrity of the workpiece and reduce the generation of surface cracks, residual stress and other defects.

Third, tool life.Good rigidity of the machine tool, the cutting process of the tool is subject to less impact and vibration, can reduce the abnormal wear of the tool, such as chipping, spalling and so on. At the same time, stable cutting conditions are also conducive to the CBN tool to maintain a good cutting edge state, to extend the life of the tool.

When the rigidity of the machine tool is insufficient, the tool will be subjected to large alternating loads, accelerating the wear of the tool and reducing the durability of the tool.Cutting parameter selection,When the rigidity of the machine tool is good, you can choose larger cutting parameters for machining, improve machining efficiency. And in the case of poor machine rigidity, in order to avoid excessive vibration and deformation, have to reduce the cutting parameters, which will affect the machining efficiency, but also may be due to the lack of cutting force and affect the normal cutting of the tool, resulting in increased tool wear.

Fourth, machining efficiency.Cutting speed and feed.Strong machine rigidity, can withstand higher cutting forces, allowing the use of greater cutting speed and feed. This can significantly improve machining efficiency and shorten machining time.If the rigidity of the machine is not enough, in order to ensure the stability of the processing, can only choose a lower cutting speed and feed, machining efficiency will be greatly reduced.

Continuous machining ability.Good machine rigidity ensures stable performance over long machining periods and reduces downtime due to machine failure or accuracy degradation. This is especially important for mass production, which can improve the continuity and efficiency of production.

In summary, machine rigidity has a critical impact on the accuracy, surface quality, tool life and machining efficiency of CBN tool turning. When turning with CBN tools, it should be ensured that the machine tool has sufficient rigidity in order to give full play to the performance advantages of CBN tools and obtain high quality and high efficiency machining results.