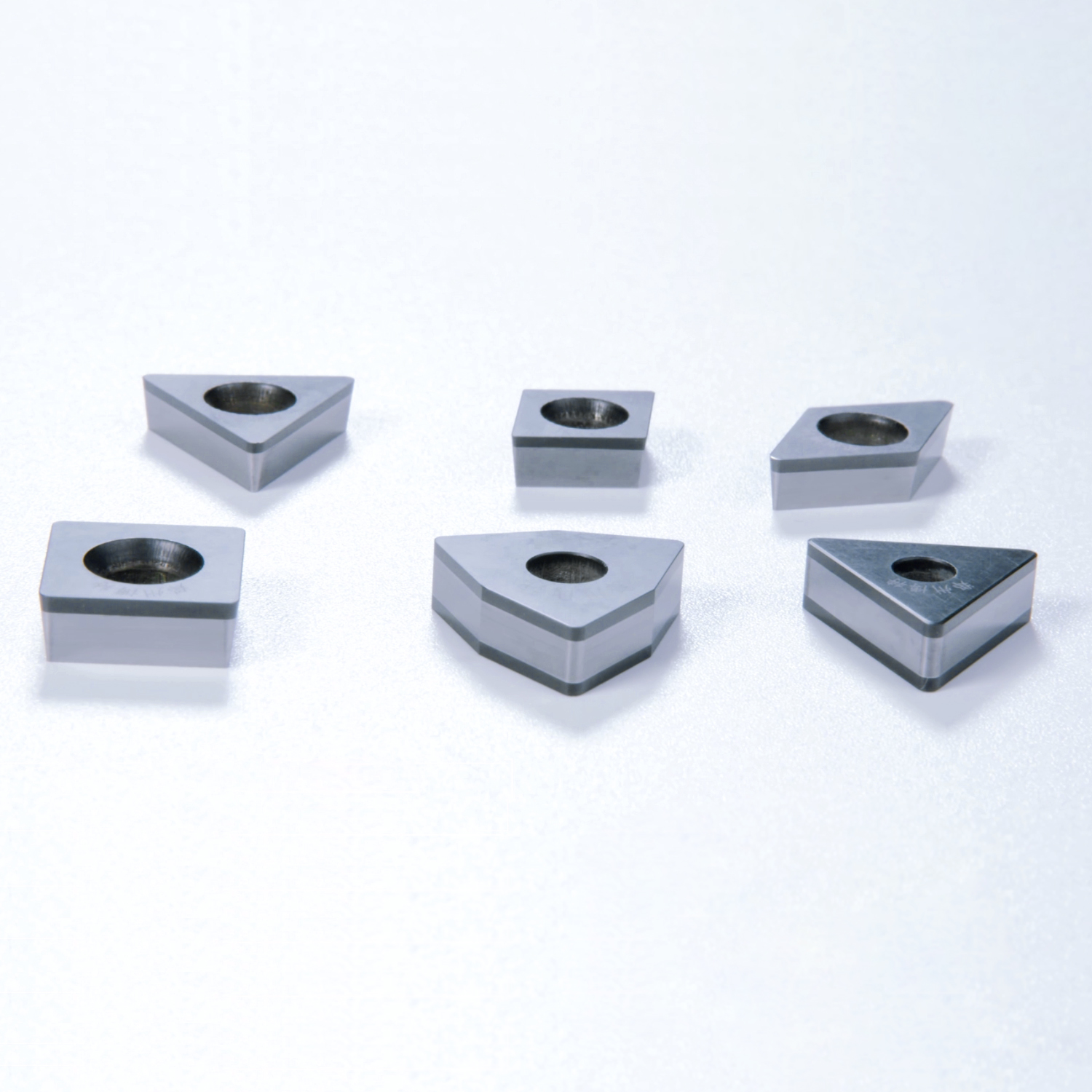

Berlt has carefully developed and launched four distinctive PCBN tool structures, which are designed to meet the precise needs of different industrial machining areas. The four structures are sintered, welded, composite and welded, each with its own unique advantages in specific applications to show excellent performance.

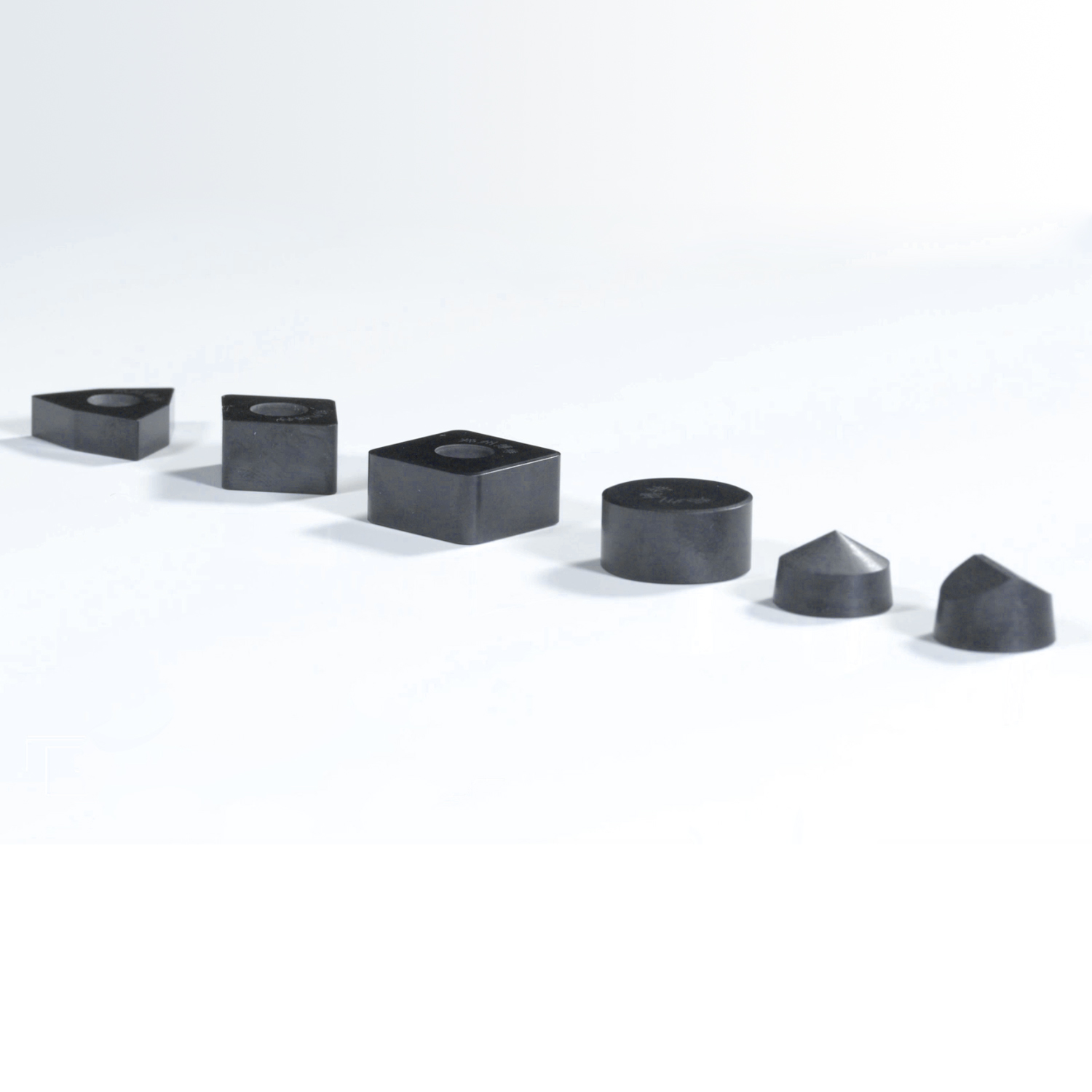

Integral sintered PCBN tools: its distinctive feature lies in the rich layout of cutting edges, which effectively enhances the utilization rate of the cutter blank material; coupled with its excellent flexural strength, it is particularly suitable for the execution of large depth of cut, high-speed cutting operations; its wide range of adaptability to the application of both roughing and finishing environments, can be handled with ease; and more support for customized notch design to meet the needs of individualized machining.

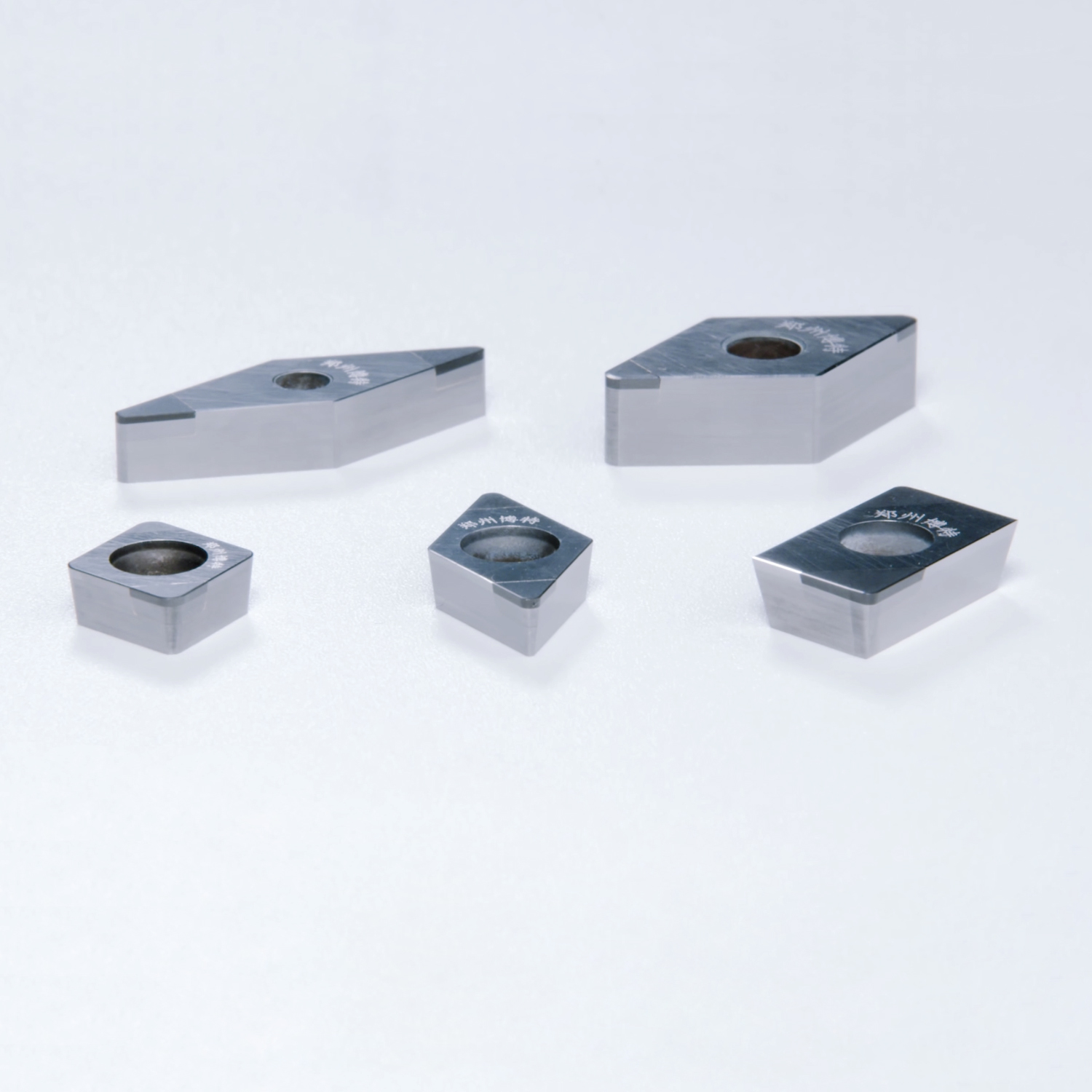

Integral welded PCBN tools: with high-strength welding process, to ensure the stability of the tool in less than 2mm depth of cut operations; its wide range of applicability also covers a wide range of roughing to finish machining scenarios; the use of the center hole positioning technology, to further enhance the stability of the machining process; in addition, this type of tool can also be a direct replacement for the coated inserts, to achieve seamless switching to improve production efficiency.

Integral composite PCBN tools: its design highlight is the composite layer and the matrix to achieve a high-strength combination, optimized for the 0 to 5mm depth of cut range; also shows a wide range of machining adaptability, whether roughing or finishing, can be excellent performance; more adapted to continuous or if intermittent machining scenarios, to ensure the continuity and stability of the machining process.

Composite welded PCBN tools: adopting the center hole positioning method to ensure high precision and stability in the machining process; mainly oriented to the field of finish machining, especially good at dealing with precision workpieces with a depth of cut of less than 0.5mm; its refined design and manufacturing process provides a reliable guarantee for high-precision machining tasks.