In the field of machining, the cutting process is a complex physical phenomenon, in which the generation and conduction of cutting heat has an important impact on tool wear, workpiece machining quality, and overall machining efficiency. Especially when cutting with cubic boron nitride (CBN) inserts, the generation and transfer mechanism of cutting heat is more special due to its unique physical and chemical properties. In this paper, we will discuss in detail the generation and emission of cutting heat during the cutting process of CBN inserts.

Cutting layer metal deformation heat During the cutting process, the cutting layer metal will experience elastic and plastic deformation. These deformation processes consume a large amount of energy, and almost all of this energy is converted into heat. Plastic deformation of the metal is internal friction, and the heat generated during the process is one of the important sources of cutting heat.

Chip heat transfer:In most cases, chips are the main means of heat transfer from cutting. Chips in the formation process will take away a lot of heat, the proportion can be as high as 50% ~ 80%. The higher the cutting speed, the larger the cutting thickness, the more heat the chips take away. Therefore, in the cutting process, reasonable control of cutting parameters, optimize the chip form, to reduce the temperature of the cutting zone is of great significance.

Workpiece heat transfer:Cutting heat will also be conducted out through the workpiece, but its proportion is relatively small, generally about 30%. The thermal conductivity of the workpiece material is an important factor affecting the speed of heat transfer. Materials with high thermal conductivity can conduct heat better and reduce the temperature of the cutting zone. On the contrary, low thermal conductivity of the material will lead to increased temperature in the cutting zone, exacerbating tool wear.

Tool heat transfer: tool in the cutting process will also absorb a certain amount of heat, but its proportion is generally small, not more than 5%. The thermal conductivity of the tool material will also affect the rate of heat conduction. Tool materials with high thermal conductivity can better conduct the heat from the cutting zone to the inside of the tool, reducing the temperature of the cutting zone. In addition, the tool geometry and parameter design will also affect the cutting heat conduction effect.

Surrounding medium heat transfer:The surrounding medium (e.g., air, cutting fluid) also absorbs part of the cutting heat. In the cutting process, the use of good cooling performance of the cutting fluid can effectively reduce the temperature of the cutting zone. Cutting fluid contact with the cutting zone by spraying or jetting, absorbing and taking away part of the heat, thus reducing the cutting temperature and improving the machining quality.

Conclusion:The generation and transmission of cutting heat is an important issue that cannot be ignored in the cutting process of CBN inserts. Through in-depth understanding of the mechanism of cutting heat generation and effusion pathway, we can better control the cutting parameters, select the appropriate tool material and cutting fluid, optimize the cutting process, thereby improving the machining quality and tool life. In actual production, corresponding measures should be taken according to specific conditions to ensure the stability and efficiency of the cutting process.

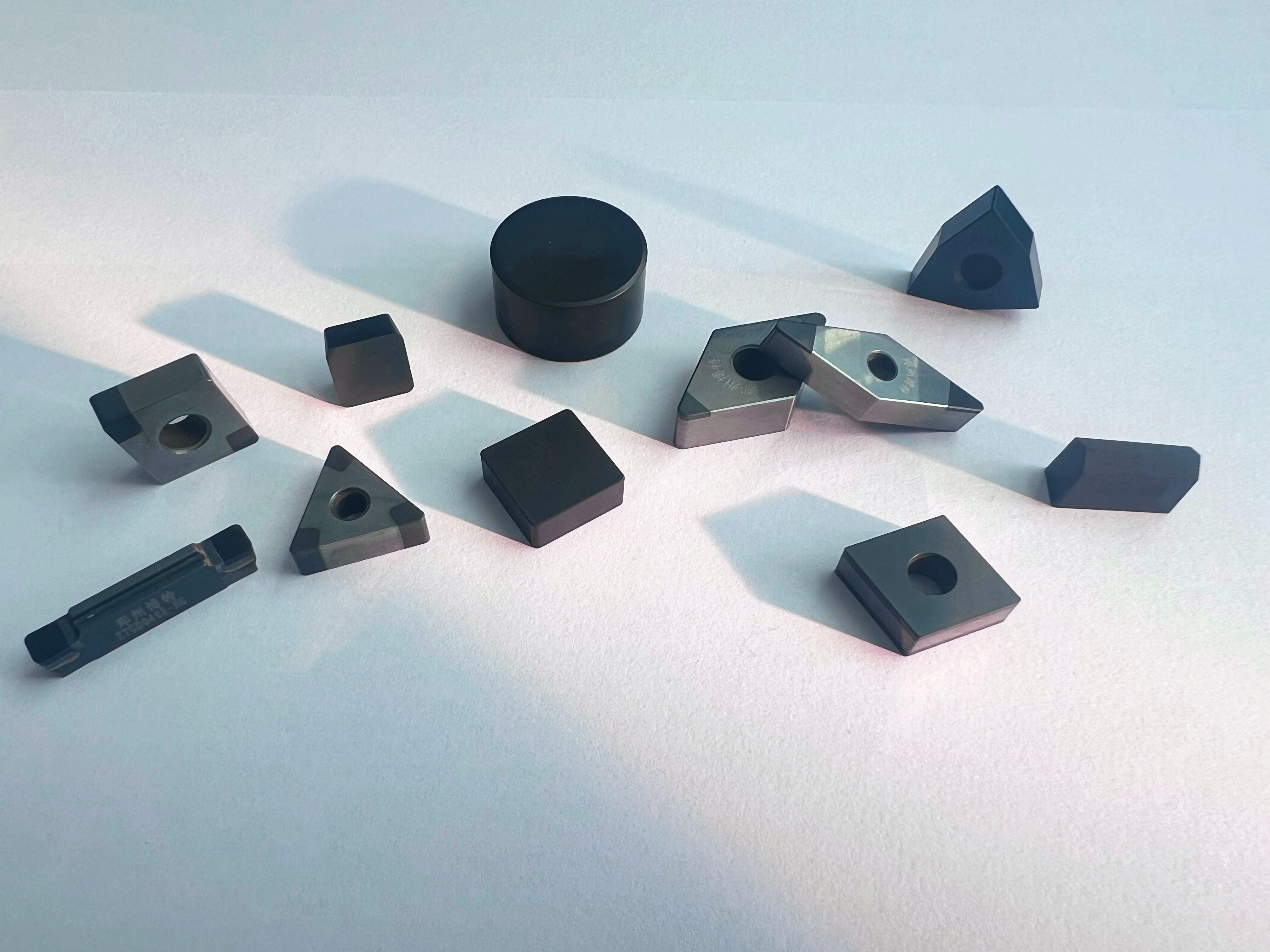

Berlt specializes in a wide range of high quality PCBN inserts