1 the significant advantages of repairing the edge of the insert technology

In the processing of hardened steel, surface roughness is affected by a variety of factors, including the amount of feed and tip angle size is particularly critical. The traditional method by reducing the amount of feed or increase the tip angle can reduce the roughness, but the former sacrifices productivity, the latter may increase the cutting force. Sharpened edge insert technology has become the preferred solution to this problem by optimizing the tip geometry and adopting a light blade design that effectively improves surface roughness while maintaining productivity.

2 Enhancement of CBN tool performance and application by sharpening inserts

Compared with conventional cemented carbide tools, CBN tools show significant advantages in the machining of hardened steel due to their high hardness and wear resistance. In particular, when combined with the technology of the dressing edge inserts, it not only significantly improves the surface quality of the parts, but also allows for higher feed rates, thus significantly increasing productivity.

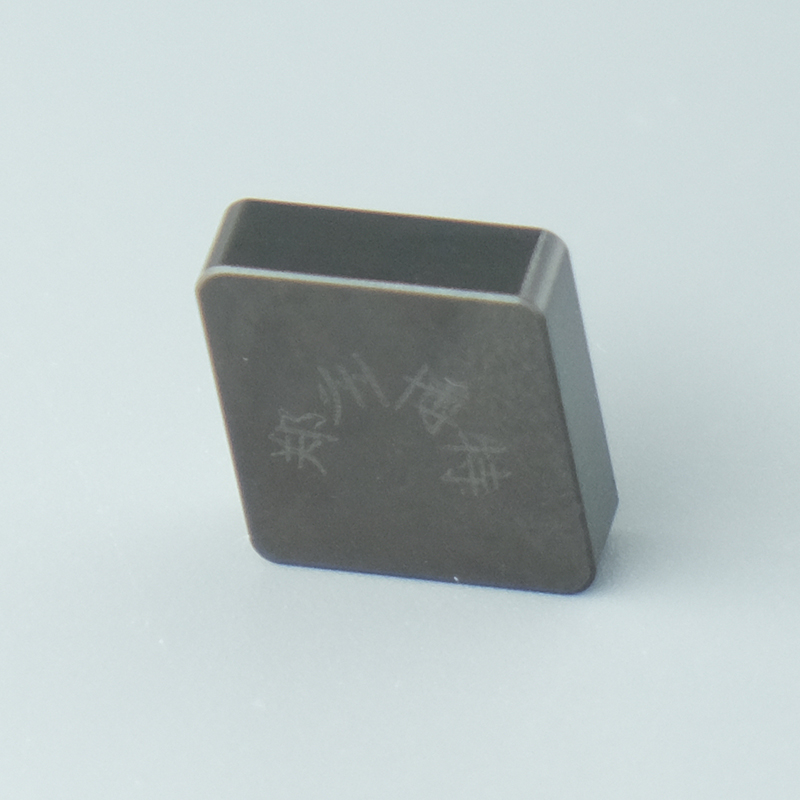

Berlt specialises in CBN inserts with sharpened edges for hard steel and cast iron machining.

Perfect surface quality, turning instead of grinding

Suitable for greater depth of cut and higher cutting speeds

Reasonable design of the dressing edge structure according to the workpiece and cutting parameters.

20 years of experience in cutting tools, trustworthy