1 The evolution of chipbreakers. After decades of technological evolution, PCBN inserts, by virtue of their excellent performance, have significantly surpassed traditional ceramic and cemented carbide tools, establishing their position as the tool of choice for high-speed cutting of ferrous metals. However, for a long time after the successful development of PCBN inserts, the design of chipbreaker flutes has not received sufficient attention. This is mainly due to two considerations: first, the high hardness characteristics of PCBN inserts make the conventional carbide tool mold groove is no longer applicable to the production of chipbreaking grooves face great technical challenges; second, in view of the PCBN inserts are usually used for machining high hardness and brittle materials, these materials in the process of machining itself less chipbreaking, and at the same time, in order to ensure that the PCBN inserts have At the same time, in order to ensure that PCBN inserts have sufficient strength to avoid the occurrence of chipping phenomenon, the traditional PCBN inserts are mainly negative chamfering and obtuse round and other structural design processing.

However, with the increasing demand for material diversity in modern manufacturing, and the ever-increasing requirements for workpiece machining efficiency and accuracy, the range of applications for precision and efficient PCBN inserts has been further expanded. Even for complex workpieces that are only partially hardened (i.e., contain both hard and soft material properties) and need to be machined in a single pass, PCBN inserts are widely used. However, these relatively soft materials often have problems with chip entanglement during the machining process, which may not only prevent the workpiece from being loaded or unloaded due to entanglement, but also scratch the surface of the workpiece, and in severe cases, even lead to the scrap of the workpiece. Therefore, the importance of chipformer design for PCBN inserts has become more and more prominent.

Chipless inserts

2 What is a chipbreaker groove for PCBN inserts.A chipbreaker groove for PCBN inserts is a specially designed insert structure that is mainly used on PCD (polycrystalline diamond) or PCBN (polycrystalline cubic boron nitride) inserts. The main purpose of the chipbreaker is to control chip flow and breakage during the cutting process to improve machining efficiency, ensure machining quality, and reduce tool wear.

Role:

Smooth chipbreaking: The chipbreaker groove can effectively control the flow of chips, so that the chips break naturally during machining, preventing them from wrapping around the workpiece or tool, thus improving machining efficiency.

Improved chip handling: By controlling the size and shape of chips, chipbreakers make it easier to handle, store and transport chips.

Improved machining quality: A smooth chipbreaking process helps to reduce cutting forces, reduce workpiece surface roughness and improve machining quality.

Extend tool life: Reduces chip wear on the tool, thus extending tool life.

Chip Breaker Structure

3 Advantages of PCBN tools with chipbreaker flutes PCBN tools with chipbreaker flutes show significant advantages over conventional PCBN tools in a number of ways. These advantages are described below:

Smooth Chip Discharge and Uniform Chip Breaking: The design of PCBN inserts with chipbreaker grooves ensures that chips are discharged smoothly during the machining process, preventing chips from wrapping around the workpiece or the tool and maintaining the continuity of the machining process.

The chipformer design allows chips to break at specific locations and be uniform in size, helping to minimize unnecessary downtime for cleanup during the machining process.

Improved machining quality: By avoiding chip entanglement and scratching of the workpiece, PCBN tools with chipbreakers maintain the surface quality of the workpiece and meet the requirements of high-precision machining.

At the same time, this design helps to minimize tool wear and increase tool life, thus ensuring consistent machining quality.

Improved machining efficiency: Smooth chip removal and uniform chip breakage make the machining process smoother and reduce downtime due to chip problems, thus improving machining efficiency.

Especially in automated production lines, PCBN tools with chipbreaking grooves can effectively deal with problems such as chip entanglement and chip scratches on the surface of the workpiece, thus ensuring the stable operation of the production line.

Reduced production costs: By improving tool life and machining efficiency, PCBN tools with chipbreaker grooves can reduce production costs and improve production efficiency.

At the same time, it also reduces the maintenance cost in the production process by reducing the downtime caused by chip problems and the frequency of tool replacement.

Wide range of applications: PCBN tools with chipbreakers are suitable for a wide range of machining scenarios, such as the machining of assembly surfaces in mechanical engineering, such as ball valves, and parts with hard and soft machined surfaces that need to be machined at the same time.

This design makes PCBN tools more widely used and can meet the machining needs of different industries and fields. In summary, PCBN tools with chipbreaker have significant advantages in terms of smooth chip removal, improved machining quality, improved machining efficiency, reduced production costs and a wide range of applications. These advantages make PCBN tools with chipbreaker groove become one of the important tools in the field of modern metal processing.

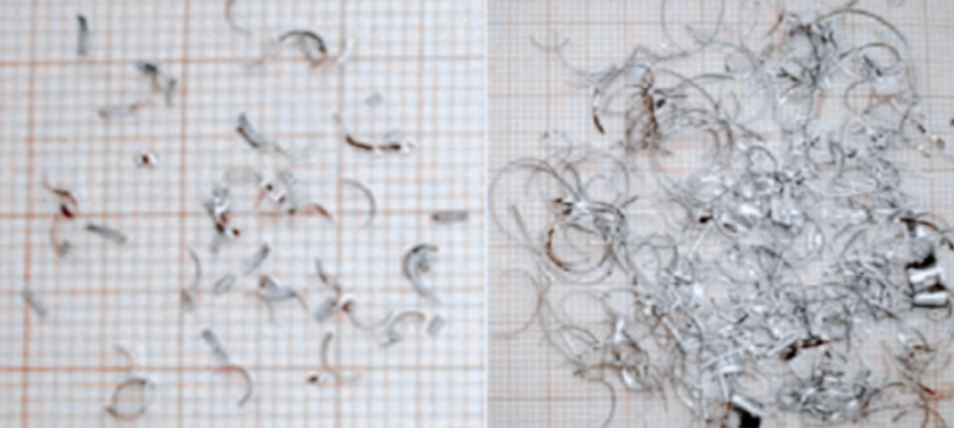

Comparison of chip sizes with and without chipbreakers

We study each link, each process, each technology, build the whole process standard system from raw materials to finished products, give full play to its own advantages of the whole industry chain resources, in order to ensure the quality of the product at the same time, effectively control the manufacturing cost of the product, with a stronger quality advantage and cost advantage, welcome to leave a message to consult.