1 Selection of base material

In view of the high hardness, excellent thermal conductivity and toughness possessed by tungsten carbide tungsten carbide, its selection as the base material for PCBN inserts is particularly common. Among them, Co, as an important solvent and binder, can effectively enhance the sintering degree of CBN, thus strengthening the overall strength of PCBN. However, care must be taken to control the content of Co in tungsten carbide tungsten carbide to avoid excessive Co content leading to a decrease in the wear resistance of PCBN inserts, which in turn shortens the service life of the tool.

2 CBN grain cleanliness and particle size

The surface cleanliness of CBN grains has a direct impact on the sintering quality of PCBN. Therefore, it is crucial to carry out strict treatment of CBN grains before sintering to remove impurities such as moisture and oxides on the grain surface. This treatment process is usually carried out under vacuum or reducing gas environment such as hydrogen and ammonia for 1~2 hours. The residue of impurities can seriously affect the bond strength between CBN grains and between them and the binder, thus reducing the strength and wear resistance of PCBN inserts.

In addition, the size of CBN particles not only affects the cutting surface quality of PCBN tools, but also has an important impact on the sintering ability of the binder. In general, a smaller CBN particle size helps to improve the cutting surface quality and enhance the impact resistance and wear resistance of the tool. However, during the sintering process, too small a particle size may lead to a decrease in the inter-particle gap, which affects the amount of binder element penetration. Therefore, comprehensive consideration should be given to selecting an appropriate mixed grain size during sintering and determining a suitable range of grain sizes based on the bonding ability of the selected binder.

3 CBN grain content

CBN content has a significant effect on the hardness and thermal conductivity of PCBN tools. With the increase of CBN content, the hardness and thermal conductivity of the tool are enhanced accordingly. High-content PCBN tools are characterized by their high hardness and high thermal conductivity, and are particularly suitable for machining high-hardness alloys and materials containing high hardness points, such as cold-hard cast iron and heat-resistant alloys. Low-content PCBN inserts, on the other hand, mostly use ceramic binder with good heat resistance, and are suitable for machining hardened steel and other materials, such as alloy steel, bearing steel, mold steel, carbon steel, etc.

4 Selection of binder

In the PCBN sintering process, the choice of binder is critical. The ideal binder should have physicochemical properties similar to those of CBN to maximize the retention of cutting performance of PCBN tools; at the same time, it should be easy to reach the melting point temperature or exhibit good plasticity at this temperature; in addition, it should be chemically active enough with respect to CBN to promote the conversion of hexagonal boron nitride (HBN) to CBN.

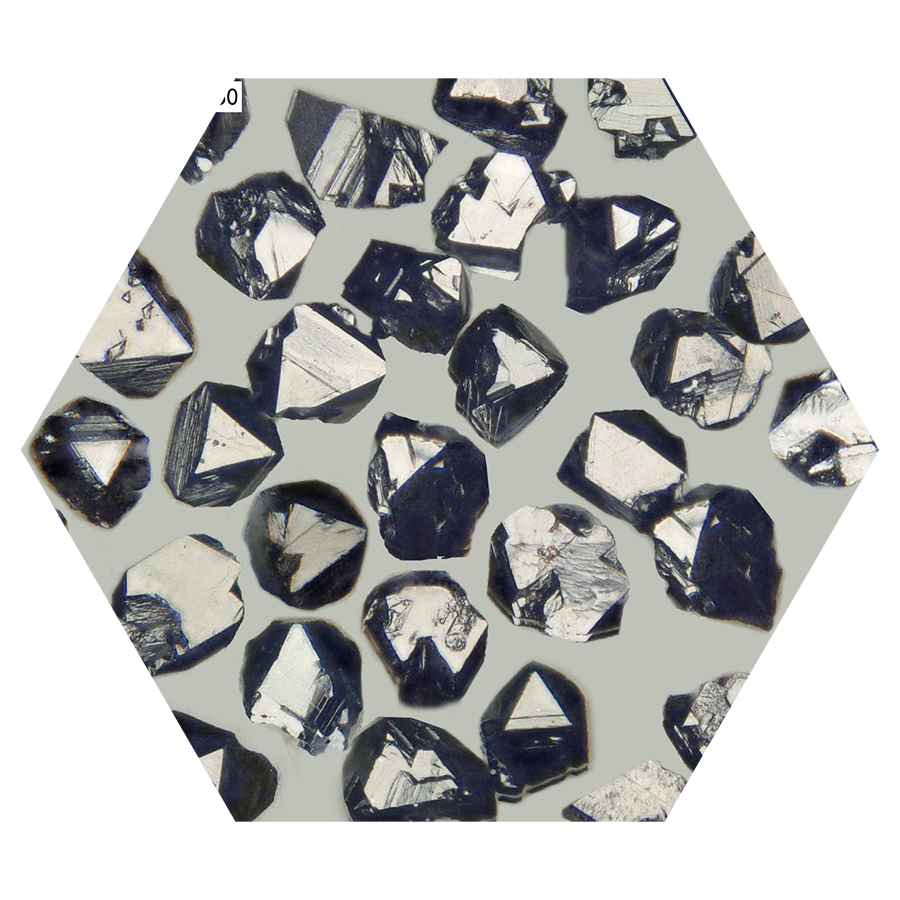

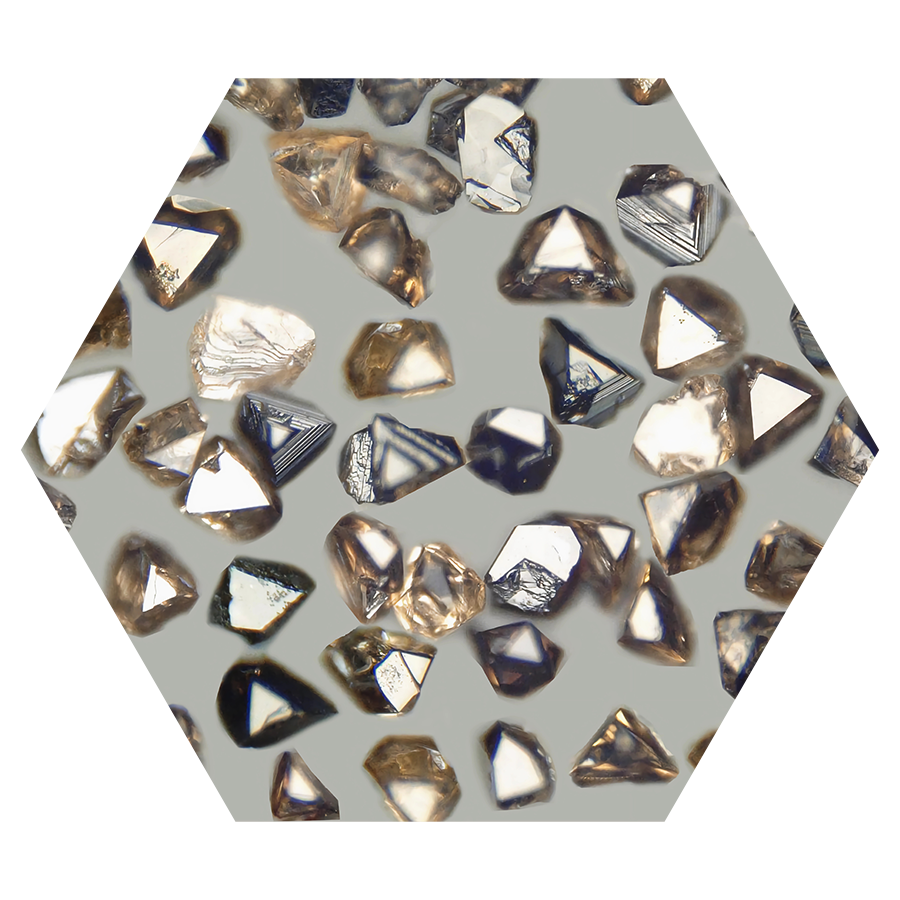

![]()

High quality PCBN tools Different models for your choice

Commonly used binders can be divided into metal binders (e.g., Ni, Co, Ti, Ti-Al, etc.) and ceramic binders (e.g., TiN, TiC, TiCN, Al2O3, etc.) according to their physicochemical properties; and can be divided into catalysts (e.g., Al, AlN, AlB2, Si, etc.) and solvents (e.g., Ti, Ni, Co, TiN, TiC, TiCN, etc.) according to their roles. The type and content of the binder have a significant effect on the performance of PCBN inserts. For example, carbides, nitrides and carbon-nitrides enhance the chemical wear resistance and impact resistance of PCBN inserts, but too high a content may reduce tool hardness and shorten its service life. Cobalt, one of the most commonly used binders, can effectively improve the sintering degree of CBN, while Ti ceramic binder can enhance the toughness of PCBN inserts. In addition, aluminum and aluminum compounds can react with CBN particles and other binders to enhance the bond strength between the particles and improve the wear resistance of the tool. mixtures of Si and Al, AlN, and AlB2 are effective catalysts for the conversion of HBN to CBN, and the addition of a small amount of these elements to the ceramic binder also enhances the bonding between the CBN and the formation of a continuous ceramic phase. The PCBN composite sheet with nickel aluminide as binder has good electrical conductivity and is suitable for processing by low-cost EDM cutting technology.