Introduction to face milling cutter: Face milling cutters have cutting edges that are perpendicular to the shank and the outer circle, and are mainly used for milling planes. The cutting edge of the outer circle is the main cutting edge, and the cutting edge on the end face plays the same role as the scraper. Face mills have shorter cutting edges than sleeve end mills.

The main material of face milling cutter: PCD is widely used in milling cutters, mainly processing various non-ferrous metals, non-metal materials and composite materials. Cubic boron nitride (CBN) is mainly used on face milling cutters. Typical grades are LDP-J-CXF (composite polycrystalline cutter block).

Advantages of face milling cutter:

Face milling cutter (also known as end milling cutter) the main use is: processing larger area of the plane. Its advantages are:

1. High production efficiency.

2. Good rigidity can use a large feed.

3. Able to perform multi-tool tooth cutting smoothly at the same time.

4. The use of insert structure to make the blade grinding and replacement more convenient.

5. Tool life is extended.

Use of face milling cutter:

Face milling cutter is a kind of multi-blade cutter, it is widely used, there are many types and specifications. Mills can be used to machine planes, grooves, steps, splined shafts, gears, threads and various forming surfaces.

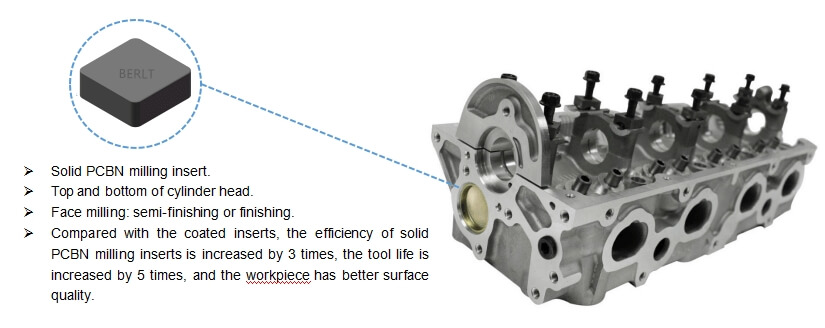

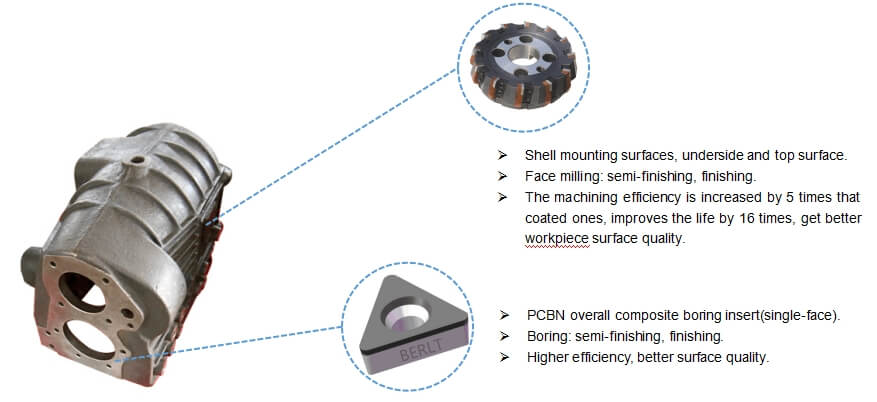

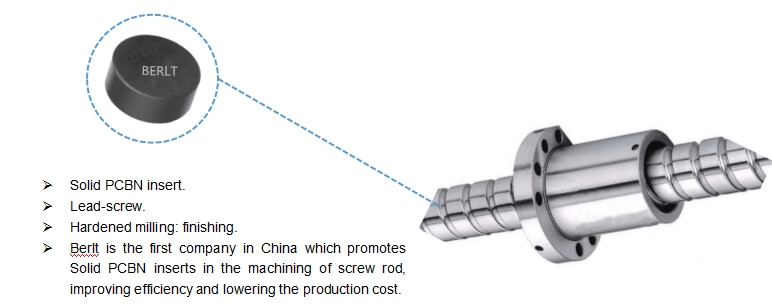

The face milling cutter produced by Nnnm adapt the CBN milling inserts, which are suitable for machining Cast hard steel(CHS),Forging hard steel(FHS),Grey cast iron(GCI),Alloy cast iron(ACI),Ductile iron(DI), etc.

If you have any hard materials for milling, welcome consult here!

Email: info@berltpcbn.com Whatsapp: + 86 15737183932