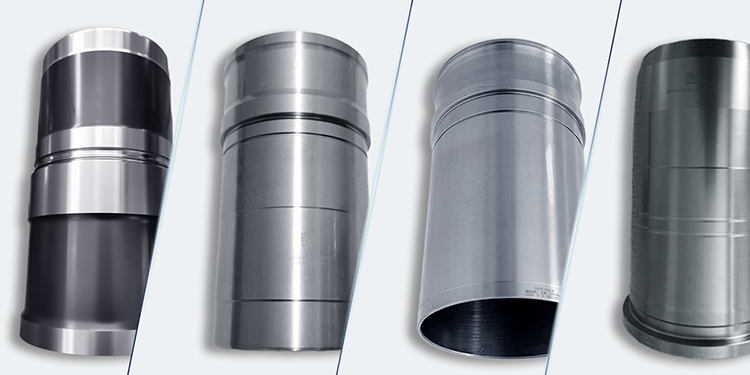

Boron cast iron is an alloy material created by adding a certain amount of boron to cast iron. Thanks to its exceptional wear resistance and strength, it is widely used in components such as internal combustion engine cylinder liners.

However, the hard boride particles within boron cast iron act like "hidden killers," posing significant challenges for traditional cutting tools: rapid tool wear, frequent chipping, short tool life, low machining efficiency, and high processing costs!

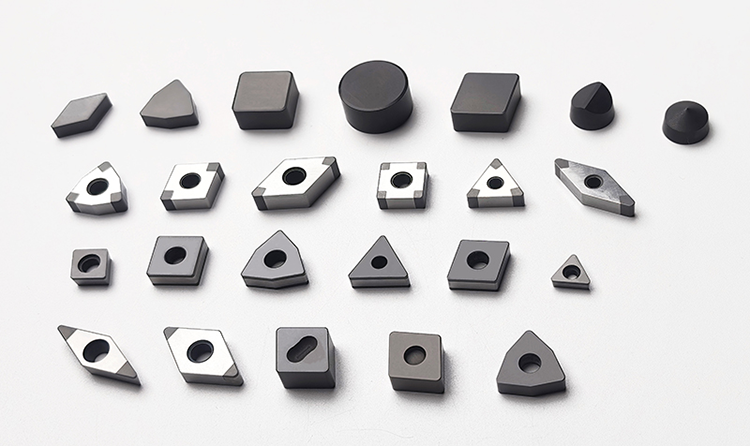

Now, Berlt Company powerfully introduces a revolutionary solution: the new PCBN grade BT7500, specifically engineered for boron cast iron. This new grade integrates super toughness, extreme wear resistance, and high efficiency, completely resolving the difficulties in machining boron cast iron and helping you achieve a dual leap in production efficiency and tool durability!

Four Core Advantages of the New PCBN Grade BT7500 Dedicated to Boron Cast Iron Machining:

·Fearless Impact from Hard Points, Strong and Tough, Resistant to Chipping, Ensures More Stable Machining

Berlt's new grade BT7500 utilizes an exclusive high-activity, high-strength binder to achieve ultra-strong and tight bonding of CBN grains. Simultaneously, it innovatively introduces nanocrystalline grains, extremely refining and strengthening the grain boundaries, endowing the inserts with outstanding toughness and high impact resistance. This effectively resists the hard spots in boron cast iron and severe cutting impacts, suppresses chipping, and ensures continuous, stable, and reliable processing.

·Extreme Wear Resistance, Improves Machining Accuracy of Products

Selected ultra-hard, high-strength CBN micro-grains, combined with a dedicated binder system of high strength and wear resistance, make Berlt's new grade BT7500 far surpass cemented carbide and traditional ceramic tools in wear resistance. This results in a several-fold increase in machining efficiency, minimal dimensional fluctuations during processing, reliably guaranteed product accuracy, and a significant reduction in rework and scrap.

·Ultra-High Machining Efficiency, Helps Reduce Costs and Improve Efficiency

Even under harsh conditions of high speed and large feed rates, the Berlt new grade BT7500 series inserts can maintain sharp cutting edges for a long time, ensuring surface quality and dimensional consistency of the machined workpieces. This not only greatly enhances production efficiency but also significantly reduces the tool cost per part due to the increased number of workpieces machined per cutting edge!

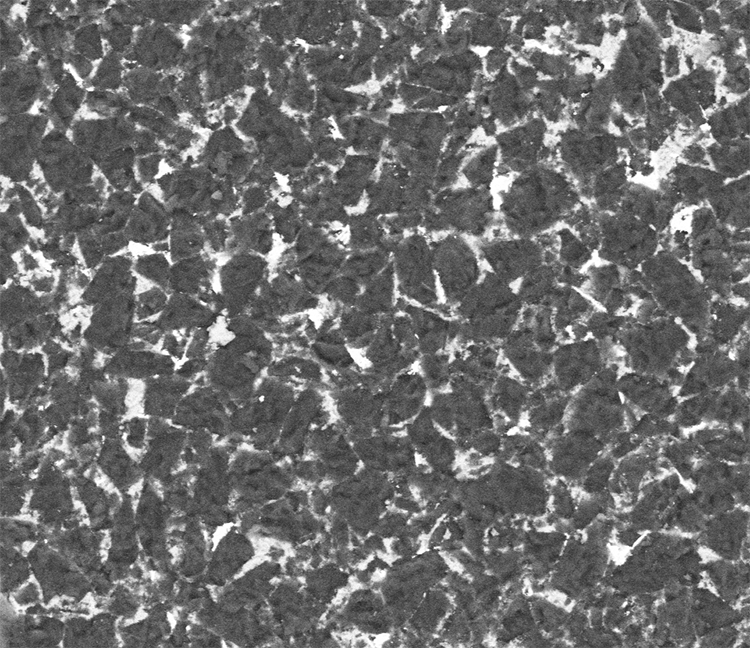

·Born for Boron Cast Iron Machining, Dense and Uniform Microstructure, More Reliable Performance

Microstructure determines macroscopic performance. Berlt's new grade BT7500 possesses a highly uniform and extremely dense microstructure, deeply optimized and designed for the high hardness and high wear resistance characteristics of boron cast iron. This fundamentally guarantees the inserts' excellent performance and ultra-high efficiency, solving the troubles of boron cast iron machining!