Cubic boron nitride (CBN) is one of the ultra-hard materials second only to diamond in hardness, offering superior thermochemical stability compared to diamond. Due to its unique chemical and thermal stability properties, CBN finds widespread applications in ferrous materials (such as hardened steel, cast iron, etc.) and brittle, hard materials.

CBN inserts boast advantages like high wear resistance, excellent thermal stability, superior chemical stability, and a low friction coefficient. They enable turning instead of grinding and can achieve high machining precision and efficiency during high-speed cutting. According to the current specifications and models available on the market from Berlt, CBN inserts can generally be categorized into four common structural forms.

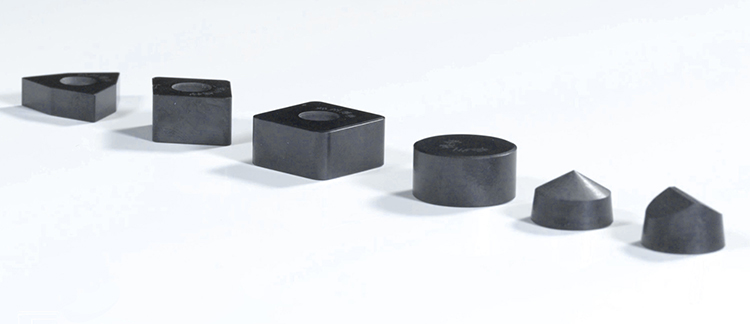

Solid CBN Inserts: These are formed by mixing CBN micropowder with binders and other materials, then sintering under high temperature and ultra-high pressure conditions. The entire insert is made of PCBN material and comes in three positioning forms: non-porous, with grooves, and through-hole.

Solid CBN Inserts feature high fracture toughness, great bending strength, excellent high-temperature red hardness, and a large number of cutting edges. Each cutting edge can be used for machining. For example, the SNGN1204 has 8 usable cutting edges.

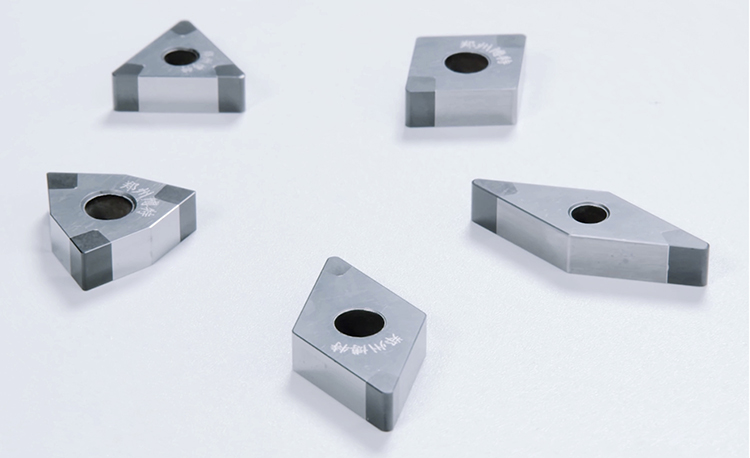

CBN braze inserts: These involve cutting monolithic sintered PCBN tips and then brazing them onto a carbide substrate under high vacuum and high temperature conditions. The alloy substrate comes with a center hole for positioning.

The cutting edge of CBN braze inserts is made of PCBN material, offering good chipping resistance. The brazing temperature for the cutting edge is over 900 degrees, and it can withstand lower cutting resistance compared to monolithic sintered PCBN inserts. However, they have fewer usable cutting edges. For example, the CNGA1204 has 4 usable cutting edges.

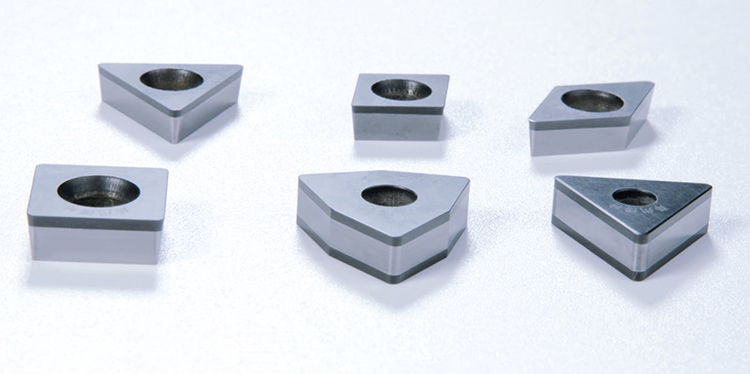

CBN overall composite inserts: These are made from PCBN composite blanks as the base material, which are cut to shape and with a center hole, then ground. The entire insert has one face or both top and bottom faces made of PCBN material, with a center hole for positioning.

CBN overall composite inserts are directly composite-formed under high temperature and ultra-high pressure, resulting in high bonding strength between the composite layer and the substrate. They can meet the requirements for roughing, semi-finishing, and finishing.

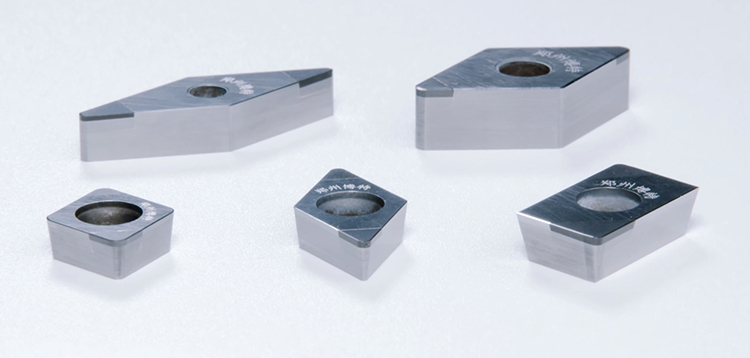

Multi-tipped CBN inserts: These involve brazing small cut pieces of PCBN composite blocks onto a carbide substrate, with a center hole for positioning. Only one cutting face is usable, and the number of cutting edges is limited.

Multi-tipped CBN inserts have half the number of cutting edges compared to monolithic brazed ones, with some inserts even having only one cutting edge. They are generally used for finishing applications, suitable for cutting depths <0.5mm and continuous finishing requirements.