During the cutting process of the roller, because of the high hardness of the cast iron roller itself, the high precision of the roller, and the complexity of the roller structure, so the cutting process of the roller has higher technology requirements than the normal parts. In order to improve the efficiency of cutting processing, ensure the accuracy of roll processing, so solving the technical problems of cutting processing of rollers is one of the key links of roller production.

According to the technical and operational difficulties of roller processing, after a long period of exploration, from theoretical analysis to actual operation, we have summarized some roller cutting technical parameters to improve roller cutting efficiency, ensure roll processing quality, and reduce processing costs. , it has good feasibility.

Ways to classify rollers as following:

(1) According to the product type, there are strip roll, section roll, wire roll, etc.

(2) According to the position of the roll in the rolling mill series, there are blank roll, rough roll, finishing roll, etc.

(3) According to the roll function, there are broken roll, perforated roll, flat roll, etc.

(4) According to the roll material, there are steel roll, cast iron roll, carbide roll, ceramic roll, etc.

(5) According to the manufacturing method, there are casting roll, forging roll, surfacing welding roll, set roll, etc.

(6) According to the rolled steel state, there are hot roll, cold roll.

Various classifications can be combined to give the roll a clearer meaning, such as centrifugal cast high chromium cast iron working roll for hot rolled strip steel.

Note: different roller materials, the CBN inserts used and the cutting parameters are different, it depends on the actual situation.

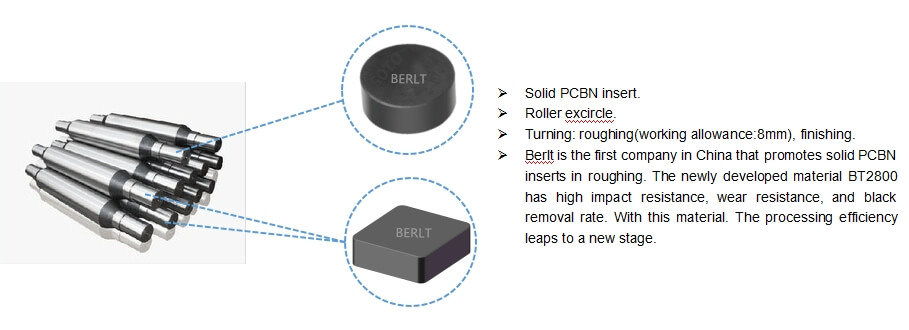

Cutting comparison of Bert’s BTS2800A materials for the roll industry as following

Turning Roll by Solid PCBN Inserts | ||

Brand | CBN of Other Brand | Zhengzhou Berlt |

Workpiece and its material | Roller(High nickel) | |

Processing part | Excircle(HSD72-78) | |

Type and grade of insert | RNMN2010 | RNMN2010(BTS2800A) |

Ap(mm) | 6-7 | |

Vc(m/min) | 40 | 40 |

F(mm/rev) | 0.6-1.0 | |

Insert life | 4h | 5h |

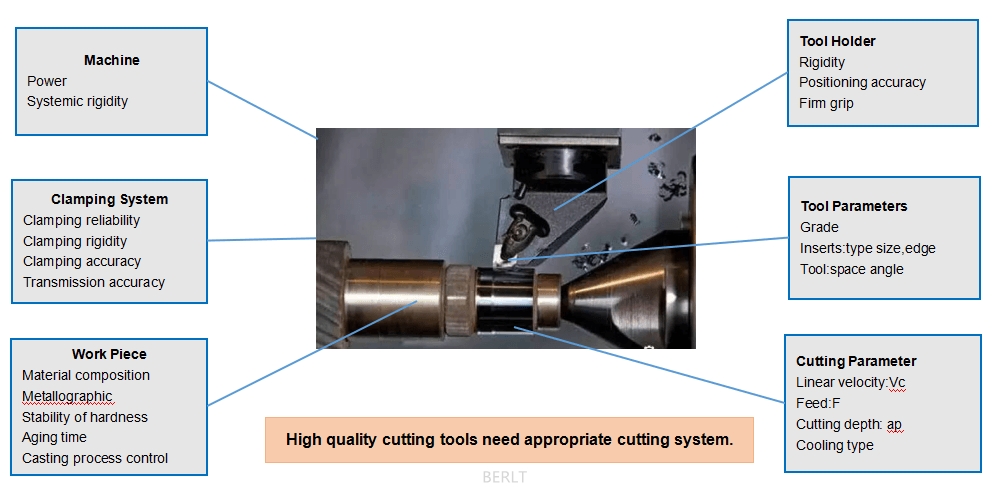

Factors that affect machining effect of PCBN insert