CBN Inserts for Cast Iron Brake Disc Machining

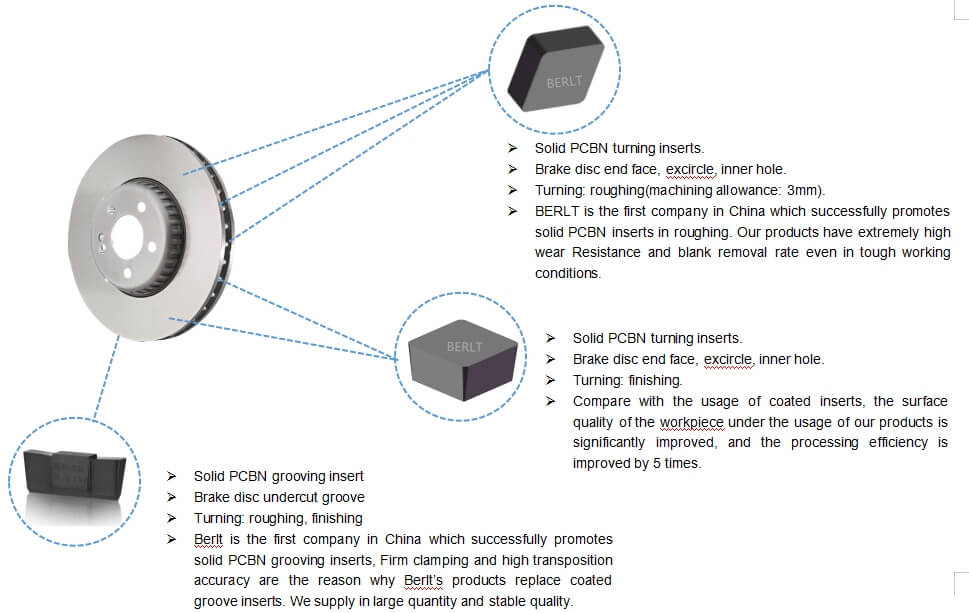

Workpiece: Brake Disc

User Enterprise: one Auto Parts Manufacturing company in Shandong

Materials: HT250

Hardness: HB180-220

Lathe: Vertical CNC Lathe

This company all used the CBN inserts from BN(China) Tech. for roughing, and the insert model is SNMN1207/CNMN1207. Both acute and obtuse angles of diamond inserts can be used, each nose of the insert can machining 200-300 pieces of workpiece(affected by workpiece’s aging, the working life is different), but the imported carbide inserts can only machining 30-40 pieces by each edge.

The market environment has higher requirements for the brake discs precision and consistency. After update the machining equipments, the brake surface finishing turning has adapted the vertical lathe integrated processing, and the original matching ceramic inserts cannot reach higher requirements.

BN(China) Tech.Co.Ltd optimize the brake surface finishing according to customer’s requirements and improve the working efficiency and quality.

Solid PCBN inserts for finishing machining brake disc(Ral.6) | ||

Inserts supplier | one ceramic inserts supplier | BN(China) Tech. |

Workpiece name& materials | disc brake(HT250) | |

Working parts | disc surface | |

Inserts model& material | SCGN090412 | SCGN090412(BTS2800) |

Cutting depth(mm) | 0.3 | |

Line speed(m/min) | 500-600 | 600-800 |

Feed rate(mm/r) | 0.15-0.2 | |

Service life | 30-40 | 100-150 |

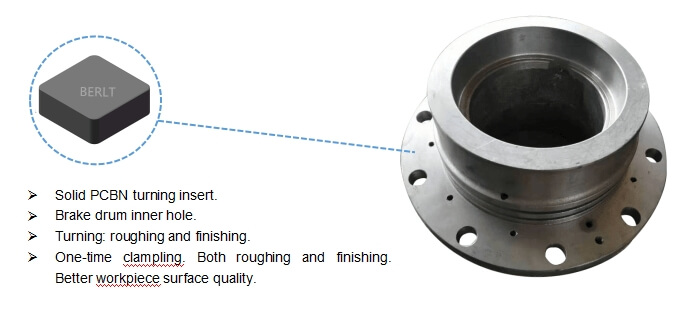

Cast Iron Brake Drum

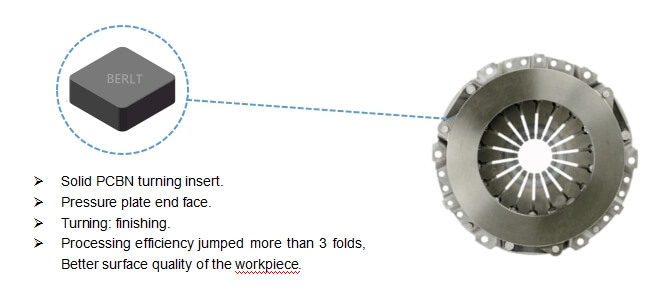

Cast Iron Clutch Pressure Plate

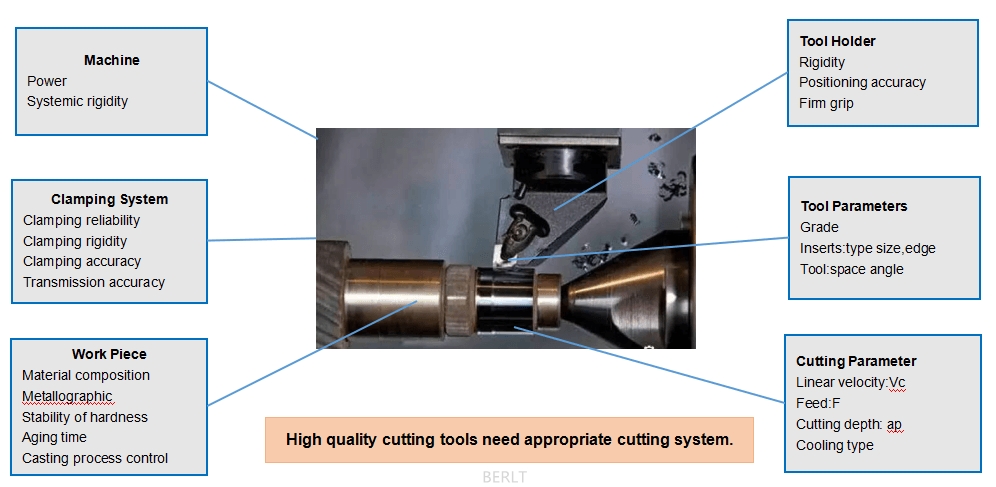

Factors that affect machining effect of PCBN insert