In the process of processing auto parts, the tools often have problems such as non-wear resistance, low efficiency, or high hardness of the parts, and immovability. Therefore, BN(China) Tech. has developed a variety of materials to respond to different materials of auto parts and specific cutting parameters. as follows.

Processing Materials | Cutting Velocity | CBN Inserts Specification | Recommended CBN Tool Grades | ||

Cutting Speed | Cutting Depth | Feed | |||

Vc(m/min) | ap(mm) | Fr (mm/r) | |||

Hardened Steel | finishing | 90-250 | ≤1 | 0.05-0.35 | BN-H05,BN-H10,BN-H11,BN-H21,BN-H20, |

Hardness ≥HRC45 | |||||

Gray Cast Iron | roughing | 400-1200 | 1-10 | 0.2-1.0 | BN-S300 |

finishing | 600-2000 | ≤1 | 0.05-0.3 | BNK30 | |

Powder Metallurgy | roughing | 80-150 | ≥0.5 | 0.1-0.5 | BNK30,BN-K10,BN-K50,BN-H21 |

finishing | 90-180 | ≤0.5 | 0.1-0.2 | ||

Engine Cylinder Block:

(1) Milling process: The BN-S300 grade of BN(China) Tech. super hard cubic boron nitride inserts is used, which significantly improves productivity and stable cutting performance, and can replace Seco tools and other international first-line brands.

(2) Boring process: BN-S300 or BNK30 is recommended. It is one of the masterpieces of cutting tool manufacturing in the engine industry with high cost performance and stable cutting performance.

(3) Stop chamfering process: customized according to customer needs, the advantage lies in stable cutting performance and high cost performance.

(4) For aluminum alloy engine cylinder block: Select BN(China) Tech. superhard PCD tool for high-speed milling plane. Its cutting speed can reach 3000m / min, which has excellent processing characteristics. For the hole system, BN(China) Tech. Super Hard PCD Reamer is recommended to improve the tool life and ensure high dimensional accuracy and surface roughness.

Engine Cylinder Head:

(1) Cylinder head fine milling process: BN-S300 grade polycrystalline cubic boron nitride inserts are recommended, which significantly improves productivity and stable cutting performance. Can replace Seco Tools and other international first-line brands.

(2)Valve chamfering process: customized according to customer needs, the advantage lies in stable cutting performance and high cost performance.

(3) Turning process of supporting valve seat: DCGW11T304 is recommended for commonly used models. The advantage is that high-speed cutting can be achieved and high finish can be obtained.

Boron Cast Iron Cylinder Liner:

(1) External turning process: The overall polycrystalline cubic boron nitride insert BN-S300 is recommended for dry cutting, and its tool durability is increased by N times compared to ceramic tools.

(2) Grooving process: customized according to customer requirements, to obtain longer tool life and higher production efficiency.

The cases of external turning are as follows:

Gear and gear shaft:

(1) Continuous cutting conditions: BN-H11 and BN-H20 inlaid cubic boron nitride inserts are recommended. Multi-edge cutting is more economical and high-speed cutting, which is N times longer than ceramic inserts.

(2) Intermittent cutting conditions: The composite cubic boron nitride inserts BN-H10 and BN-H21 are recommended for stable cutting performance and can replace imported tools with advantages.

Gearbox Housing:

(1) Milling process: The material of the overall polycrystalline cubic boron nitride insert BN-S300 is recommended, and the production efficiency of coated carbide tools is significantly improved, and the tool life is increased by N times.

(2) Boring process: Welding cubic boron nitride inserts (including composite and inlay) are recommended, which significantly improves production efficiency and achieves higher surface quality.

(3) For aluminum alloy gearbox housings: BN(China) Tech. Superhard can provide PCD milling, boring, reaming, drilling and other tools, greatly improving production efficiency, ensuring higher dimensional accuracy and reducing production costs.

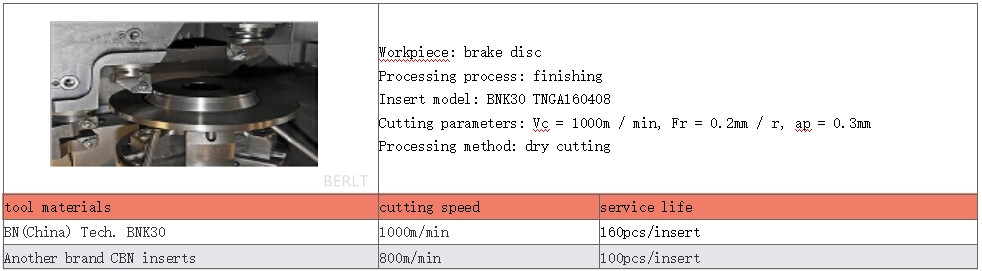

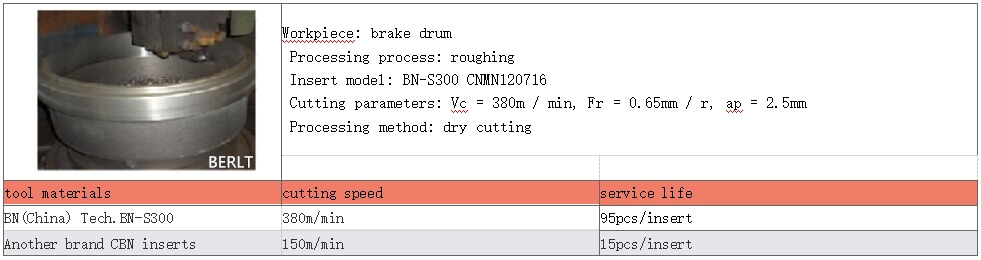

Brake disc (drum):

(1) Turning-roughing process: The material is HT250. The overall polycrystalline cubic boron nitride insert is recommended. Its performance is stable and the efficiency is doubled.

(2) Turning-finishing process: The material is HT250. Both integral cubic boron nitride inserts and inlay cubic boron nitride inserts can be used. The advantage is that the efficiency is significantly improved, and the service life of coated carbide tools is increased by N times.

.

Pulley:

The material is HT250, which is mainly used for end face processing. Welding cubic boron nitride inserts (including composite and mosaic) are recommended. The advantages are: stable cutting performance and doubled production efficiency.

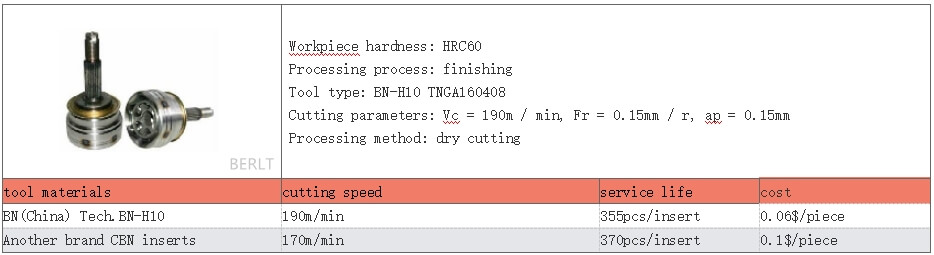

Ball cage universal joint:

Process: The hard turning process after heat is recommended. The compound cubic boron nitride insert is recommended, with high cost performance, stable cutting performance, and intermittent processing.

The processing cases are as follows:

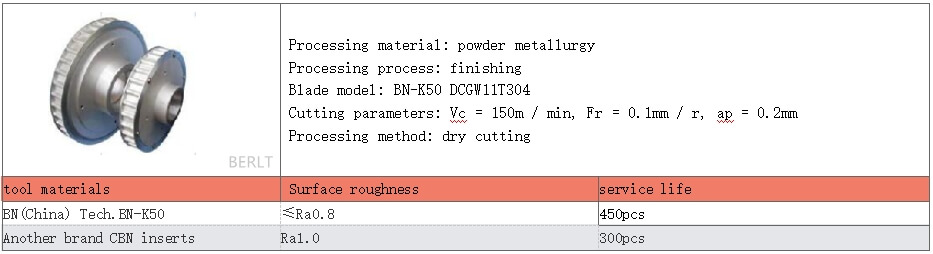

Synchronous Pulley:

The material is powder metallurgy. Due to the porous structure, the cutting edge of the cutting tool is sharply worn. At this time, Bote ultra-hard welded cubic boron nitride blades are recommended. The advantages are: sharp blades, stable cutting performance, and tool life compared to CBN The tool is increased by 50%.

Synchronizer hub:

The material is powder metallurgy. Due to the porous structure, the cutting edge of the cutting tool is sharply worn. At this time, Bote ultra-hard welded cubic boron nitride inserts are recommended. The cutting performance is stable and the tool life is 45% longer than that of a brand CBN tool.

Wheel hub:

The material is aluminum alloy. Bote super-hard PCD tools are recommended for more stable cutting performance, longer tool life and increased efficiency and cost. Bote can provide non-standard customized services.

Piston:

The material is aluminum alloy. BN(China) Tech. super hard PCD cutter is recommended, which can be processed at high speed, with stable product quality, high precision and long life. It also provides non-standard customized services.