- Mode:

CNMN120716

- Type:

Solid PCBN Inserts

- Application:

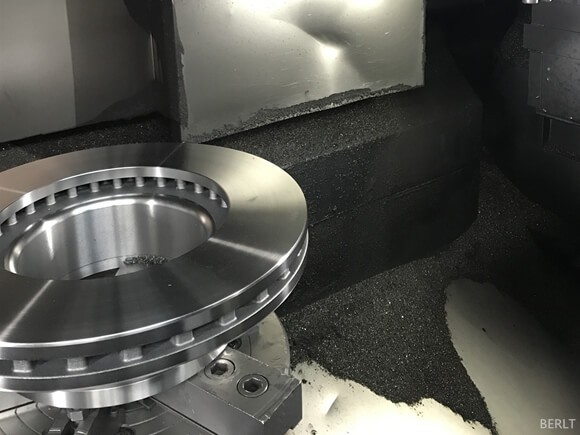

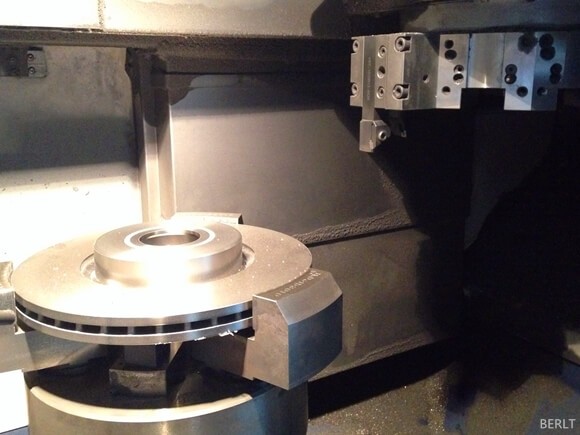

Automotive Industry

There is a client from Korea,with the factory has used cemented carbide tools for the process of brake dics. But that showed a bad performance that there are only 40 workpieces can be processed by each tool,and it resulted the very short working life. The tools they use now are our PCBN cutting tools.

| Tools Model:CNMN120716 |

| Piece material:HT250 | |

| Hardness:HB180-220 |

Solid PCBN inserts for finishing machining brake disc(Ral.6) | ||

Inserts supplier | one ceramic inserts supplier | BN(China) Tech. |

Workpiece name& materials | disc brake(HT250) | |

Working parts | disc surface | |

Inserts model& material | SCGN090412 | SCGN090412(BTS2800) |

Cutting depth(mm) | 0.3 | |

Line speed(m/min) | 500-600 | 600-800 |

Feed rate(mm/r) | 0.15-0.2 | |

Service life | 30-40 | 100-150 |

Each tool can work reach 220-260 piece,working life enhance by 5-7 times than cemented carbide tool.

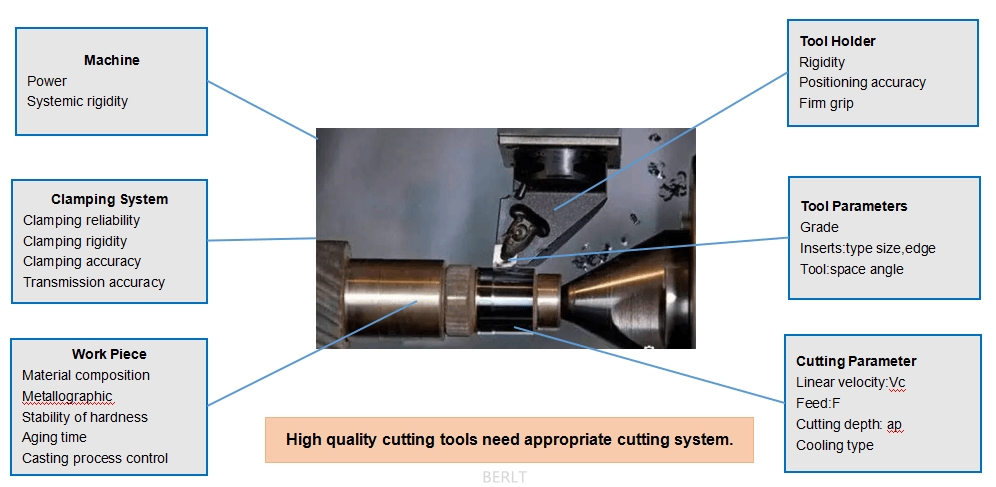

Factors affecting the cutting performance of CBN inserts

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible