- Mode:

- Type:

- Application:

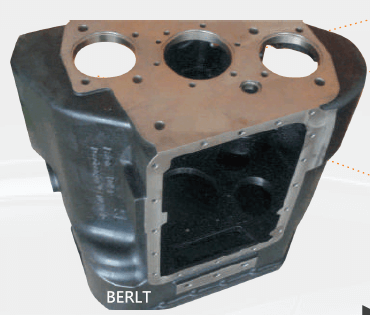

Gearbox Case Boring Processing Case

The gearbox housing is one of the important parts of a car. It assembles parts such as shafts, sleeves and gears to keep them in the correct position. Therefore, the assembly accuracy of these parts and box components and the performance and life of the machine after assembly are largely determined by the processing quality of the box itself.

Gray cast iron is often used as the gearbox material, because gray cast iron has good wear resistance, machinability, and low cost. Cast steel parts can also be used. For the machining of cast iron gearbox housings with slag inclusions and pores, traditional machining methods are difficult to achieve in order to fully meet the processing characteristics of the gearbox housing. In order to reduce the time for tool setting and tool change, Batch processing efficiency. Multi-blade indexable CBN inserts (multi-tooth milling cutters) can be preferred when processing the gearbox housing, which is convenient for loading and unloading. One blade can process 70-100 pieces, and another blade can be replaced after the cutting edge is worn. It can improve the machining efficiency by 50-70%. When processing the hole system of a small transmission case, it is often performed on a universal milling machine such as a vertical milling machine and a horizontal milling machine. The hole processing is relatively difficult.

A T-type (TCGW series) CBN insert developed by Berlt company is specially used for boring. The CBN boring insert can guarantee the required finish, dimensional accuracy and geometric accuracy. The car-replacement grinding process is widely used in the mass production of heavy-duty automobile transmissions, which solves the traditional grinding process and has significant production benefits. In addition, the generated chips are easy to recycle, which reflects the green and environmentally friendly processing technology.

CBN solid composite boring gearbox case | ||

Tool manufacturers | Foreign ceramics | Zhengzhou Berlt |

Workpiece name and material | Gearbox case gray cast iron | |

Processing part | Box hole | |

Tool model and material | TCMW160408 | TCGW160408-F BT9000 |

Cuttingdepth(mm) | 0.2 | |

Line Speed(m/min)Le(m/min) | 1000 | |

Feed rate(mm/r) | 0.12-0.15 | |

Tool life | 20 | 80 |

Business case | a domestic transmission factory |

Machine tool | vertical machining center |

Workpiece name | Transmission case |

Processing part | hole in the box |

Workpiece material | gray cast iron |

Hardness | HB200-300 |

Processing procedure | fine boring |

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible