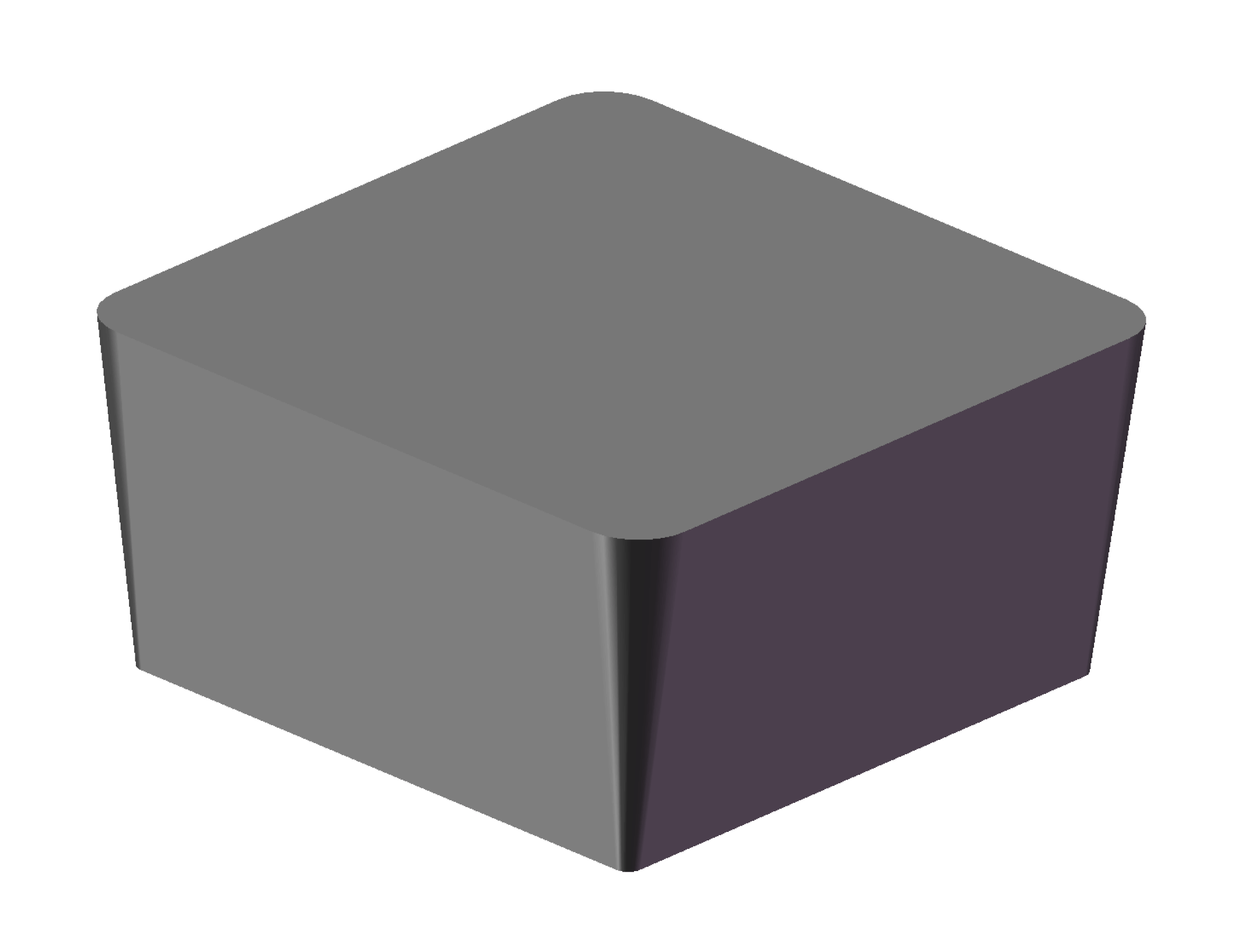

SCGN Series CBN Inserts

Processed Material: Hardened Steel, high strength cast iron,Powder Metallurgy,Gray Cast Iron

Processing Methods: Finishing, semi-finishing and roughing.

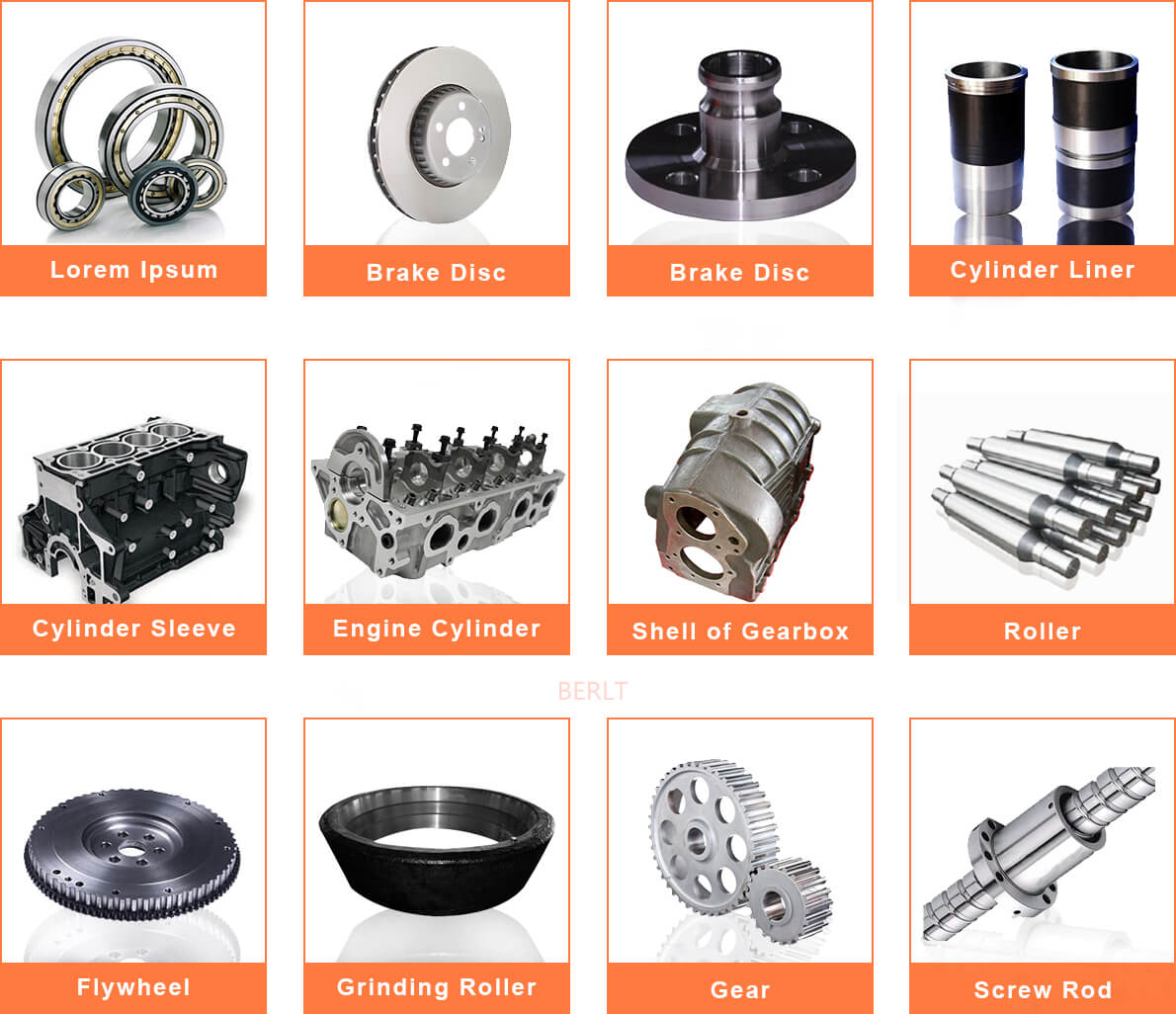

Application: Brake disc, compressor flange, brake drum, gears, valve, bearing, roller, grinding roller, engine cylinder head, cylinder sleeve, cylinder block, etc.

SCGN series solid CBN inserts have a 7 °cutting edge rake angle, which reduces the friction between the flank face and the machining surface, and cooperates with the rake angle to adjust the sharpness and firmness of the cutting part of the tool, enhance the edge strength and improve the cutting of the inserts performance.