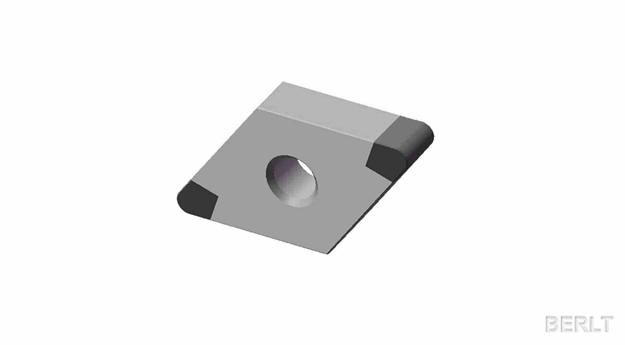

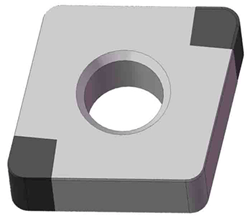

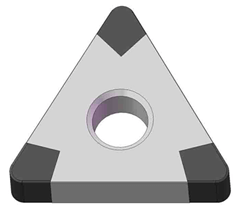

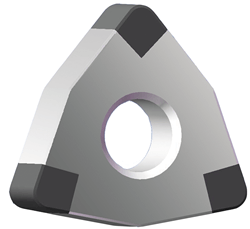

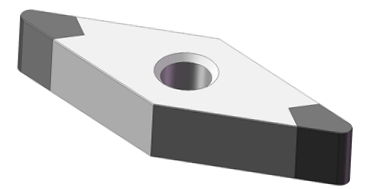

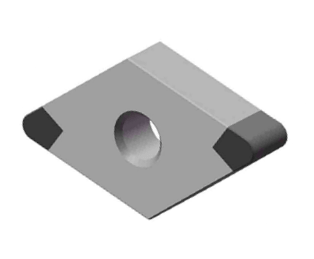

DNGA-ZH Series Inserts

Processed Material: Hardened Steel, high strength cast iron, powder metallurgy, gray cast iron etc.

Processing Methods: Finishing, semi-finishing and roughing.

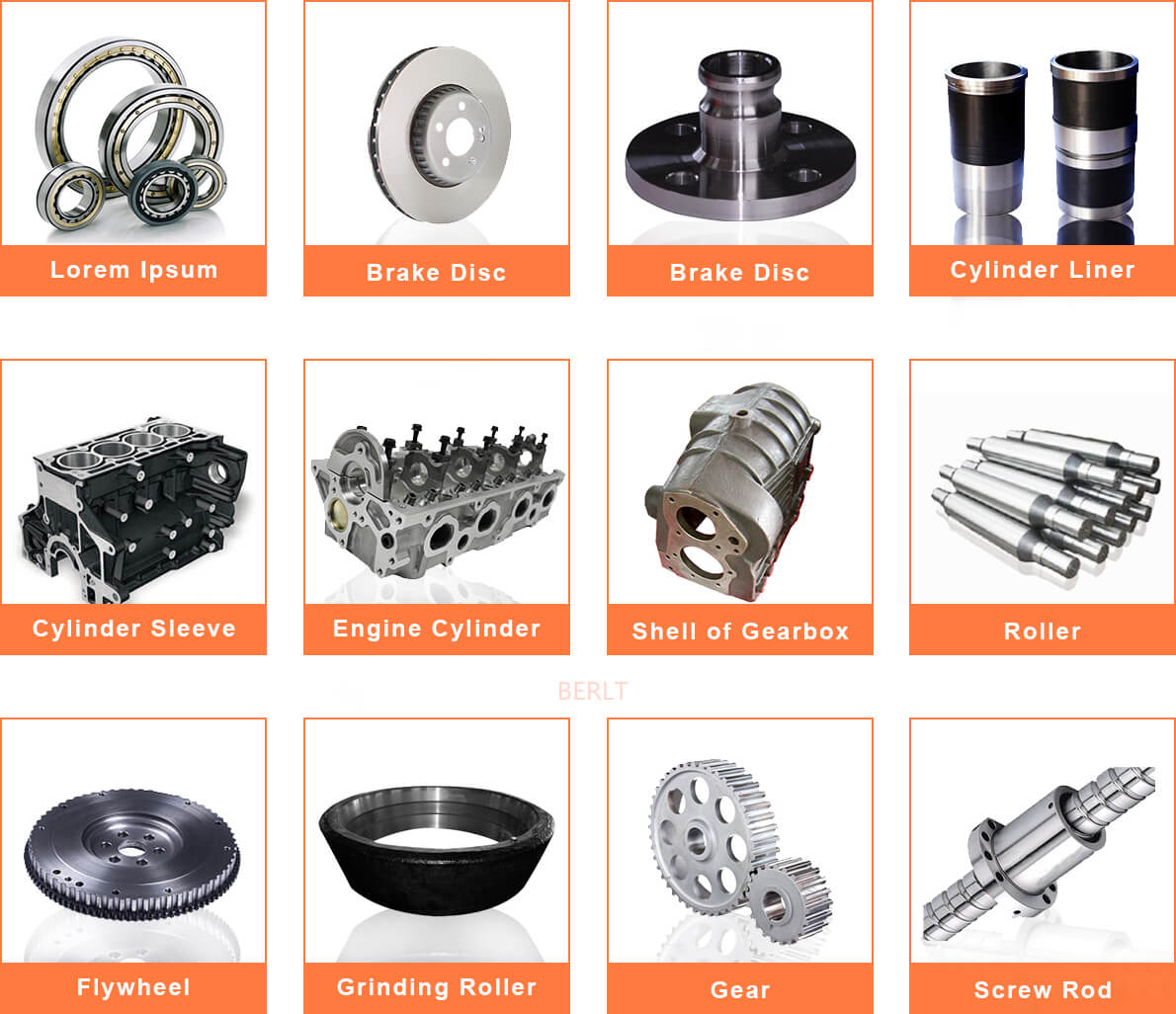

Application: Brake disc, compressor flange, brake drum, gears, valve, bearing, roller, grinding roller, engine cylinder head, cylinder sleeve, cylinder block, etc.