Zhengzhou BERLT focused on the research and development of super hard tools, and first proposed four structural forms of PCBN inserts.We focus on professionalism, a strong technical team, strict quality inspection processes, and multi-department collaboration to create your PCBN inserts for you.

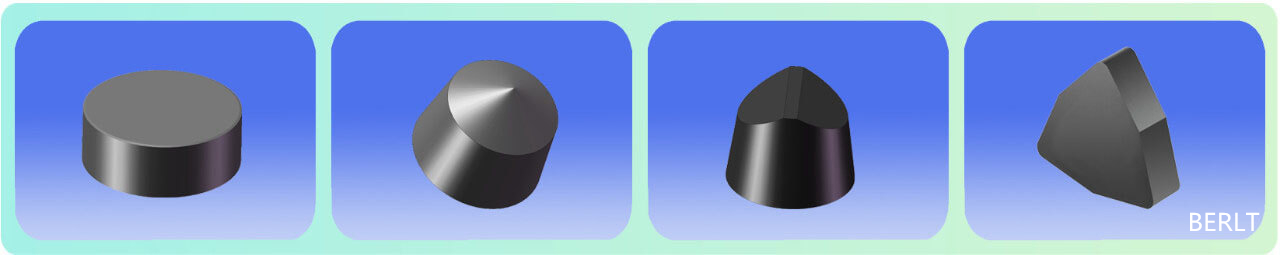

Part 1 Solid PCBN Inserts

Physical and geometrical characteristics:

1. High fracture toughness;

2. High bending strength;

3.Withstands 1400 degrees.

4. The number of tool tips is large, each tip can be cut. For example, C1204, 4 blade points at 80 degrees, plus 8 blade points at obtuse angles.

Application scope and advantages:

1. Can meet rough, semi-finish and fine processing;

2.Suitable for continuous, weak intermittent and strong intermittent

environmental cutting;

3. Suitable for large cutting depth and high speed cutting;

4. Can process countersinks or through holes, making clamping more firm.

5. This structure is the first choice for hard steel processing.

6. Can be regrind unlimited times, high blade utilization;

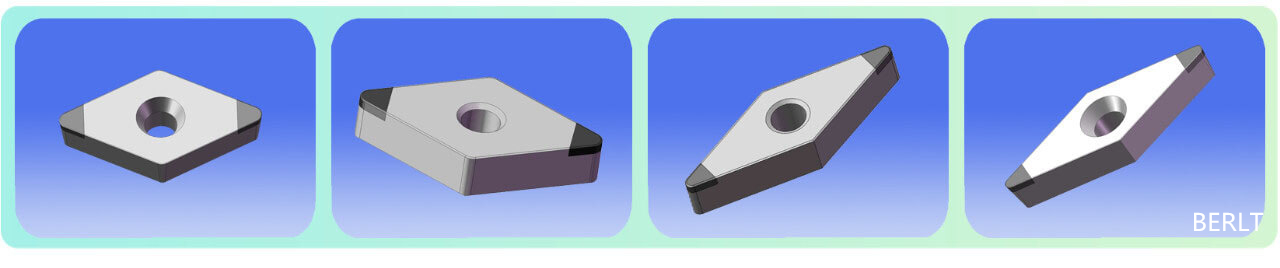

Part 2 Multi-tipped PCBN Inserts

Physical geometry:

1. The blade tip is made of sintered material and has good chipping resistance.

2. The welding temperature is more than 900 degrees, and the tip can withstand 750 degrees cutting temperature without falling off;

3. The welding tip can withstand cutting resistance lower than the overall sintering and overall composite blade.

4. Only sharp-edged blades are available. Such as C1204, there are 4 blade points.

Application scope and advantages:

1. Can meet rough, semi-finish and fine processing;

2. High welding strength, can withstand higher cutting temperature and cutting force.

3.Suitable for cutting conditions <3mm processing conditions, can meet strong intermittent, weak intermittent and continuous processing environment.

4. Corresponds to the full clamping tool bar, which can directly replace the coated blade without replacing the tool bar.

5. This structure is recommended for hard steel processing.

6. It can be regrinded, but the frequency is limited.

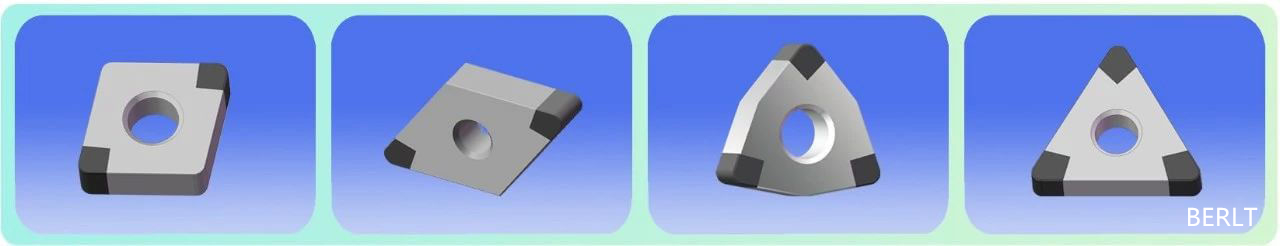

Part 3 PCBN Brazing Inserts

Physical and geometrical characteristics:

1. The blade tip is a composite material, which is brittle and has poor chipping resistance;

2. Welding temperature of 800 degrees, can withstand cutting temperature of 650 degrees without falling off.

3. The number of cutting edges is doubled compared to the overall welding. Some small blades have only one tip.

Application scope and advantages:

1. Suitable for semi-finishing and finishing needs;

2. Suitable for cutting depth <0.5mm, weak intermittent and continuous finishing environment;

3. The probability of desoldering is increased under the environment of high cutting temperature.

4. Can't regrind.

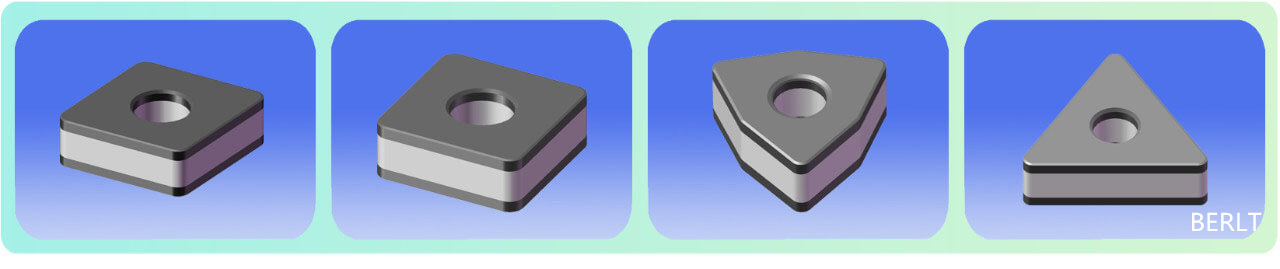

Part 4 Overall composite PCBN Inserts

Physical and geometrical characteristics:

1. The blade is a composite material, which is brittle and easy to chip.

2. It is directly compounded under high temperature and pressure, and has the same high temperature resistance characteristics as the overall sintering blade;

3. The number of cutting edges is the same as the overall sintering blade.

4. The bending strength and fracture toughness are worse than the overall sintered blade.

Application scope and advantages

1. The bonding strength between the composite layer and the substrate is high,

2. Suitable for 0-5mm cutting depth, continuous and light intermittent cutting;

3. It can meet the needs of rough machining, semi-finishing and finishing;

4. Can be regrind an unlimited number of times.