Diamond tools are mainly used for high-speed machining of wear-resistant non-ferrous metals and non-metallic materials. Cubic boron nitride tools are chemically inert to ferrous metals and other hard-to-machine materials in the field of high-speed cutting is widely used. Superhard cutting tools rely on unique material advantages, in the automotive industry, mold manufacturing and machine tool processing and other areas of significant results, both to optimize the process, but also significantly improve the processing efficiency. China in the field of superhard materials outstanding resource advantages, upstream raw materials market competition and abundant supply. 2023, China's superhard cutting tools industry market size of more than 7 billion yuan, although foreign brands dominate the competition in the industry, but the domestic enterprises, although a late start, but in the rapid catching up, the market gap is gradually narrowing.

With the continuous expansion of new downstream application scenarios, super-hard cutting tools are expected to become a priority in some areas. New materials continue to iterate, so that the industry presents a variety of cutting tool materials coexist situation. Due to the wide range of cutting tool applications and various types of product demand differences, it is difficult to form a single mainstream product, cost-effective to become an important factor in determining the market share. On the one hand, the high technical content of super-hard material cutting tools, complex production processes, many industrial manufacturing processes have been difficult to use traditional carbide cutting tools. On the other hand, at this stage, the price of superhard cutting tools is much higher than cemented carbide tools, the price gap makes it difficult to show the cost advantage in large-scale production. However, in the future, with the reduction of production costs, super-hard cutting tools are expected to emerge in certain application scenarios. Specific applications include: first, the automotive industry, superhard cutting tools have been widely used in precision machining, technology is relatively mature; second, the aerospace field, superhard cutting tools by virtue of its tool life, machining accuracy and stability gradually involved; third, the field of consumer electronics, precision structural parts processing in the 3C industry has begun to introduce titanium alloys and other high-end materials, superhard cutting tools, cost-effective advantage gradually appeared; fourth, the humanoid robots In the field of consumer electronics, super-hard cutting tools can meet the requirements of hard milling, which can help to improve the performance and production capacity of ball screws, and expand a broader space for the application of humanoid robots.

The scale of the industry and application areas continue to broaden, the scale effect is expected to drive down the cost. The choice of tool material has a significant impact on machining accuracy, surface quality, tool life, cutting efficiency and production costs. Tools in the cutting process need to withstand high pressure, high temperature, friction, impact and vibration and other forces, so the tool material must have the following basic properties: first of all, the hardness and abrasion resistance is extremely important, the hardness of the tool material should be higher than the material of the workpiece, and the higher the hardness the better the abrasion resistance. Secondly, the need to have high strength and toughness to withstand the cutting force, impact and vibration, to prevent the tool from brittle fracture or collapse. In addition, the tool material should also have good heat resistance, can maintain stability in high temperature environment, and has excellent oxidation resistance. Finally, the tool material should have good process performance, such as forging, heat treatment, welding and grinding, etc., and at the same time have a high degree of economy, in order to meet the machining needs at the same time to achieve cost-effective.

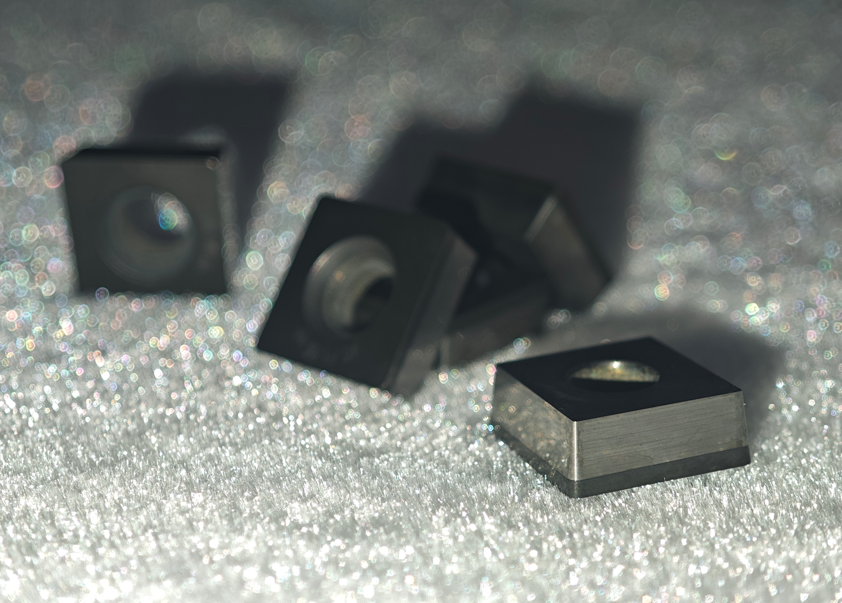

Superhard cutting tools are in the modern engineering materials processing on the background of higher requirements for productivity and processing quality came into being. Superhard cutting tool materials are mainly diamond and cubic boron nitride (CBN) two types, its chemical composition and hardness formation mechanism with carbide and high-speed steel and other cutting tool materials are different. Cubic boron nitride has a face-centered cubic crystal structure, and diamond is composed of carbon elements with a crystal structure similar to that of cubic boron nitride. Compared with other materials, they are extremely hard and have both excellent wear and heat resistance, good thermal conductivity, process performance, and low coefficient of friction. In practical applications, synthetic diamond composite (PCD) tools and cubic boron nitride composite (PCBN) tools dominate the market.