In the arena of machining, turning has always played an important role. However, when the chipping edge, an unwelcome guest, intrudes into the turning process, it may bring a lot of trouble to the production.

Turning is a method of material removal through workpiece rotation and tool movement. In this seemingly organized process, chipping can appear as an unexpected storm. First, let's explore the reasons for chipping. On the one hand, poor tool selection may be the culprit. If the material and hardness of the tool does not match the material being machined, or the geometry of the tool is not reasonably designed, it will be easy to withstand excessive pressure during the cutting process, resulting in chipping. For example, if a tool with insufficient hardness is used when machining a material with high hardness, the tool is likely to chip under the strong cutting force. On the other hand, irrational setting of cutting parameters is also a common causative factor. Excessive cutting speed, excessive feed and depth of cut, will make the tool in an instant to withstand a huge load, beyond its capacity, and then trigger chipping.

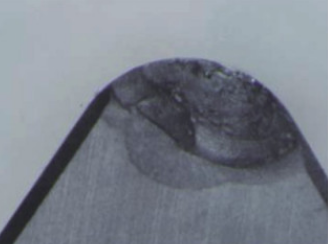

Once the chipping occurs, its consequences should not be underestimated. First of all, it will seriously affect the machining quality. After chipping the tool can not guarantee the cutting accuracy and surface roughness, so that the processed workpiece size deviation, surface roughness and other issues. Secondly, chipping will reduce productivity. It takes time to replace the tool, and frequent chipping may also lead to machine downtime, disrupting the production schedule. In addition, chipping increases machining costs. Damage to the tooling requires replacement of the tooling, which undoubtedly increases the cost of production for the organization.

In order to avoid chipping during turning machining, we can take a series of measures. In terms of tool selection, it is necessary to choose the appropriate tool material and geometry according to the characteristics of the material to be processed, processing requirements and other factors. For example, for materials with high hardness, carbide tools can be selected; for high-precision machining, coated tools can be selected. In terms of cutting parameter settings, cutting speed, feed and depth of cut should be reasonably adjusted according to the actual situation of the tool and workpiece. At the same time, you can also optimize the machining process, improve the stability of the machine tool and other ways to reduce the probability of chipping.

In short, chipping is a problem that requires great attention in the turning process. Only in-depth understanding of the causes of chipping, to take effective preventive measures to ensure the smooth progress of turning, improve machining quality and productivity, reduce processing costs. Let us take a rigorous attitude and scientific methods to deal with the challenge of chipping in the turning process, and contribute to the development of the machining industry. Zhengzhou Berlt is a leading manufacturer of CBN cutting tools, with decades of experience in the field, for the chipping problem summarized a series of response options, welcome your message.