Slurry pump is one of the indispensable equipment in the separation process of ore dressing and coal preparation plants. Its basic structure is composed of impeller, pump casing, pump shaft, and bearing. The power parts also includes motor, paired wheel or belt wheel coupling, and the wear-resistant parts also include liner bushing. At present, about 80% of the slurry pumps are used in the mining industry. Due to the harsh ore selection conditions in the ore dressing plant, the service life of the slurry pump is generally low in this stage. Of course, different ores have different abrasiveness. If the relative abrasion is reduced in the concentrate conveying and other sections, the overall service life of the pump will be longer, and the ash and slag pump. Thirdly, in the coal washing industry, due to different working conditions, large coal blocks and coal gangue are easily blocked. The design requirements of the slurry pump are very high, and good products can be durable. Pump housing and other parts need to undergo rough and fine machining to achieve assembly accuracy, and it is more convenient to use.

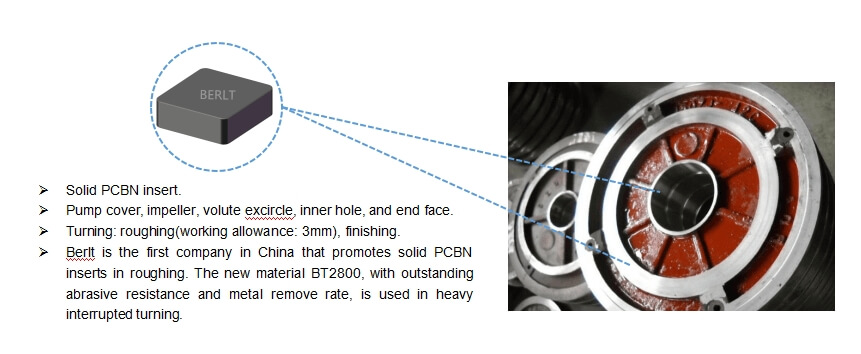

At present, 70% to 80% of domestic slurry pump production plants have adopted hard turning technology, and it is better to use CBN tools (cubic boron nitride) that are widely used in the field of hard turning, which successfully solves the problem of processing deformation and low yield, eliminating the two processes of annealing and quenching, save a lot of man-hours and power, and also solve the processing problems caused by casting pores such as pores and trachoma. Berlt newly developed BTS2800 PCBN cutting tools (polycrystalline cubic boron nitride) has extremely high abrasion resistance, high blank removal rate and high impact resistance, and is capable of severe interrupted turning conditions.

Processing parts: slurry pump impeller, sheath

Workpiece material: wear-resistant high chromium alloy

Hardness: HRC58-62

Processing process: rough turning, semi-finishing turning

Blade: Cubic boron nitride monolithic blade

Cutting depth: ap = 3mm

Linear speed: Vc = 80m / min

Feed amount: f = 1mm / r